Nothing ruins a Saturday faster than a Toro lawn mower not starting when you’re ready to cut. The good news: many no-start issues have simple fixes you can do in minutes—like refreshing stale fuel, cleaning the air filter, or checking the spark plug connection. Start with a quick prime, fresh fuel, and a firm pull; for many Toro models, that’s enough to bring it back to life.

If that doesn’t solve it, don’t worry. This comprehensive guide covers common causes and step-by-step solutions for Toro push mowers, self-propelled models, Recycler series, and even some walk-behind engines from Briggs & Stratton, Kohler, and Honda typically used on Toro. You’ll learn how to diagnose fuel, spark, air, and safety systems, fix the problem safely, and keep it from happening again.

Common Causes of a Toro Lawn Mower Not Starting

- Stale or contaminated fuel (older than 30–60 days)

- Clogged carburetor or fuel jet

- Dirty or over-oiled air filter blocking airflow

- Spark plug fouled, loose, or damaged

- Safety switches not engaged (bail control, blade/drive control)

- Flooded engine from over-priming or tipping wrong direction

- Blocked fuel cap vent causing vacuum lock

- Low engine oil level on models with low-oil shutoff

- Choke not set or auto-choke sticking

- Sheared flywheel key (after hitting a rock)

- Faulty ignition coil (rare, but possible)

- Bad or old fuel line/pulse line (cracked or collapsing)

How to Fix a Toro Lawn Mower Not Starting

Work from simplest to more advanced. Plan 10–60 minutes depending on the issue.

Method 1: Quick Checks and Fast Restarts

Diagnosing the Issue

- Time since last run: If >30 days and fuel wasn’t stabilized, suspect stale gas.

- Pull feel: Strong resistance and one or two pops means you likely have spark; no cough at all points to fuel/air.

- Smell of fuel after pulls: Fuel smell suggests flooding.

Fix Steps

1) Confirm safety controls:

– Squeeze and hold the Operator Presence Control (bail bar) tightly against the handle.

– On blade brake clutch (BBC) models, ensure blade control is disengaged for starting.

– For self-propelled, don’t squeeze the drive bail while starting.

2) Set choke:

– Manual choke: Move to CHOKE when starting cold, then to RUN after it fires.

– Auto-choke models: No setting needed.

3) Use fresh fuel:

– If the tank fuel is older than 30–60 days, siphon it out and add fresh, ethanol-free fuel if available (or E10 with fuel stabilizer).

4) Prime and start:

– If equipped, press the primer bulb 3–5 times until you feel resistance.

– Pull the starter cord firmly. Try up to 3–4 pulls.

5) If flooded:

– Open choke (RUN), don’t prime, hold throttle open if available, and pull 6–8 times.

– Wait 10 minutes and try again.

Testing

- Engine should start within a few pulls. If it sputters and dies, move to fuel/air steps.

Method 2: Fuel System and Airflow Fixes

Diagnosing the Issue

- Starts with starter fluid but won’t stay running: carburetor or fuel delivery problem.

- Won’t start at all, air filter very dirty: airflow restriction.

- Tank “whoosh” when you open the cap: blocked cap vent.

Fix Steps

1) Replace or refresh fuel (5–10 minutes)

– Drain old fuel.

– Refill with fresh 87+ octane gas. Add stabilizer (per bottle directions).

2) Check fuel cap vent (1 minute)

– Loosen the cap slightly and try starting. If it starts, replace a blocked cap.

3) Clean/replace air filter (5 minutes)

– Paper filter: Tap gently to remove debris or replace if dark/plugged.

– Foam pre-filter: Wash with warm soapy water, dry completely, oil lightly, squeeze out excess.

– Important: A soaked foam pre-filter can choke the engine.

4) Inspect fuel line and fuel filter (if equipped)

– Look for cracks, kinks, or collapse.

– Replace if brittle or leaking.

5) Clean the carburetor jet and bowl (15–30 minutes)

– Turn fuel valve off (if present) or clamp the fuel line.

– Remove the carburetor bowl nut (often the main jet) and bowl.

– Clean the jet holes with carb cleaner and a soft bristle (no drilling).

– Clean the bowl; remove varnish and debris.

– Reassemble with the bowl gasket seated. Turn fuel on and check for leaks.

6) Optional: Full carburetor clean (30–60 minutes)

– Remove air box, linkages, and carb.

– Disassemble and soak metal parts in carb cleaner; blow out passages.

– Reassemble carefully. Replace gaskets if damaged.

Testing

- Prime 3–5 times (if applicable) and pull. If it runs then dies, repeat jet cleaning or check for air leaks at the carb-to-intake gasket.

Method 3: Spark Plug and Ignition Checks

Diagnosing the Issue

- Strong fuel smell from exhaust but no fire: likely no spark.

- Occasional pop/backfire: weak spark or timing issue.

- After impact with rock, immediate no-start: possible flywheel key.

Fix Steps

1) Inspect and clean spark plug (5 minutes)

– Remove the boot and plug.

– Check gap per engine spec:

– Briggs & Stratton: typically 0.030 in (0.76 mm)

– Honda GCV: 0.028–0.031 in (0.7–0.8 mm)

– Kohler: 0.030 in (0.76 mm)

– Replace if fouled, oily, or electrode worn. Use the OEM-specified plug (e.g., NGK BPR6ES/BR2LM variants depending on engine).

– Hand thread and snug to spec (typically 14–20 ft-lb); don’t over-tighten.

– Ensure the boot clicks on firmly.

2) Test spark safely (5 minutes)

– Use an inline spark tester or ground the plug body to the engine and pull the cord. Look for a strong blue spark.

– No spark? Confirm the bail bar is held and the kill switch cable isn’t shorted.

3) Inspect ignition coil air gap (advanced)

– Remove the blower housing/shroud.

– Check coil to flywheel magnet gap: common spec is 0.010–0.014 in (0.25–0.36 mm). Use a business card as a spacer.

– Replace coil if you have no spark and kill wire is not grounding it.

4) Check flywheel key (after blade impact)

– Remove recoil housing and flywheel nut.

– Inspect key for shearing; replace if sheared to restore timing. Torque flywheel nut per engine spec.

Testing

- Reinstall plug and try starting. If spark is restored, engine should fire within 1–3 pulls.

Method 4: Safety Systems, Oil, and Choke Issues

Diagnosing the Issue

- Engine doesn’t even cough and feels like it has compression: bail/kill switch might be cutting spark.

- Auto-choke models hard to start cold: choke plate not closing fully.

- Sudden no-start after an oil change or mowing on a slope: low-oil shutdown activated (on equipped engines).

Fix Steps

1) Operator presence/kill circuit

– Inspect the cable from bail bar to engine brake. Adjust cable so the brake fully releases when the bail is squeezed.

– Check the kill wire from coil to switch; ensure insulation intact and not pinched.

2) Oil level check (2 minutes)

– Set mower on a level surface.

– Check dipstick; fill to the upper mark with SAE 30 or 10W-30 per Toro/engine spec.

– Important: Overfilling can cause hard starting and smoking.

3) Choke function

– Manual choke: Verify linkage moves freely from CHOKE to RUN.

– Auto-choke: With engine cold, confirm choke plate is closed; when warm, it should open. Clean sticky linkages; replace a faulty thermostat spring if needed.

4) Flooding recovery

– Remove the spark plug; pull the starter 5–10 times to clear cylinder; let it air-dry for 15 minutes.

– Reinstall plug, no priming, choke off; try again.

Testing

- If the safety cable or oil level was the issue, you should get immediate spark and start.

How to Prevent Future Starting Issues

- Use fresh gasoline and add fuel stabilizer if storing more than 30 days.

- Avoid ethanol-heavy fuel; E0 or E10 preferred.

- Run the engine dry or use stabilized fuel before off-season storage.

- Replace the air filter every season or 25 hours; check monthly in dusty conditions.

- Replace the spark plug every season or 100 hours.

- Change oil annually or every 25–50 hours per your model.

- Clean the mower deck to prevent debris clogging cooling fins and linkage.

- Store indoors and keep the fuel cap vent clean.

Pro Tips

- Keep a dedicated small engine fuel can with stabilizer premixed; label the date.

- If you must tip the mower, tip it with the carburetor/air filter side up; tipping the wrong way floods the cylinder and saturates the filter.

- A short burst of carb cleaner or starting fluid into the intake can quickly isolate fuel vs. spark issues. If it fires briefly, focus on the carb/fuel system.

- Replace inexpensive parts first: fuel line, filter (if equipped), air filter, spark plug, and carb bowl gasket.

- On Toro Recycler models with Briggs engines, a clogged main jet in the carb’s bowl nut is the top culprit; clean both the center and side holes.

- Keep a spare pull cord; frayed or slipping cords make starting far harder and can snap mid-season.

- After hitting an object, check for a bent blade and inspect the flywheel key before repeated starting attempts.

When to Call a Professional

- You have no spark after checking the kill circuit, plug, and coil gap.

- The flywheel key is sheared and you’re not comfortable removing the flywheel.

- Severe carb varnish that persists after cleaning, or you prefer a full rebuild/replace.

- Repeated flooding with fuel in the oil (oil smells like gas) indicating a stuck float/needle.

- Cracked intake manifold or persistent vacuum leak.

- Engine has low compression (feels too easy to pull, or fails compression test).

What to look for:

– Certified small engine technician with experience on your engine brand (Briggs & Stratton, Honda, Kohler).

– Transparent diagnostics fee and written estimate.

Typical costs (varies by region):

– Tune-up (plug, filter, oil, carb clean): $80–$150

– Carburetor replacement: $60–$150 parts + labor

– Ignition coil: $35–$90 parts + labor

– Flywheel key and timing reset: $60–$120

Warranty notes:

– Newer Toro mowers may have engine warranties separate from the mower. Modifying carb settings or using non-recommended fuel can affect coverage. Check your manual.

FAQ

Q: My Toro mower only starts with starter fluid. What’s wrong?

A: That almost always indicates a fuel delivery issue—clogged main jet, varnished carb passages, or blocked fuel line/cap vent. Clean the carburetor bowl and jet, ensure the cap vent is open, and use fresh fuel.

Q: How do I know if my engine is flooded?

A: You’ll smell strong gasoline, the plug will be wet, and the mower may sputter but not start. Open the choke, remove the plug to air out the cylinder, let it sit 10–15 minutes, then try starting without priming.

Q: Can bad gas cause a Toro mower not to start?

A: Yes. Gasoline starts to go stale in as little as 30 days. Ethanol can attract moisture and form varnish that clogs jets. Drain and replace with fresh, stabilized fuel.

Q: What should the spark plug gap be?

A: Check your engine manual. Common gaps: Briggs & Stratton 0.030 in, Honda GCV 0.028–0.031 in, Kohler 0.030 in. Always use the plug type specified for your engine.

Q: My mower died while mowing and won’t restart. What should I check?

A: Check for debris around the flywheel and cooling fins, confirm oil level, remove and clean the air filter, inspect the fuel cap vent, and verify spark. If you hit an object, inspect the flywheel key.

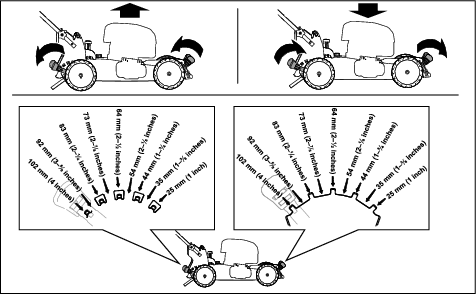

Q: Is it okay to tip my Toro mower on its side?

A: Yes, but always keep the carburetor/air filter side up. Tipping the wrong way can flood the engine and soak the air filter with oil.

Q: How often should I service my Toro mower to prevent no-start issues?

A: At minimum once per season: change oil, replace air filter and spark plug, clean carburetor bowl/jet, and add fresh stabilized fuel. In dusty conditions, check the air filter monthly.

Alternative Solutions

Sometimes a persistent no-start points to parts that are cheaper to replace than to rebuild, especially on older units. Consider:

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace carburetor with OEM | Fast fix, restores factory performance | Higher cost than cleaning | Severely varnished carbs |

| Aftermarket carb kit | Low cost, often includes gaskets/lines | Variable quality, tuning may differ | Budget repairs |

| Pre-mixed ethanol-free fuel (cans) | Long shelf life, cleaner starts | Expensive per gallon | Infrequent users, storage periods |

| Push-to-start electric mower | No fuel issues, low maintenance | Upfront cost, battery care | Small/medium lawns, convenience |

Get Your Toro Lawn Mower Working Again

By following this guide, you now have multiple ways to fix a Toro lawn mower not starting:

– Quick checks: safety bails, choke settings, fresh fuel, and correct starting technique

– Fuel and air fixes: clean/replace air filter, clear the carburetor jet, verify cap vent and fuel line

– Spark and ignition: new plug, spark test, coil gap, and flywheel key inspection

– System checks: oil level, choke linkage, and flooded engine recovery

– Preventive maintenance to avoid future no-start headaches

Don’t let a simple fuel or spark issue sideline your weekend. Start with the quick fixes, work methodically through the steps, and you’ll have your Toro purring again in no time.

Have you fixed your Toro mower with these steps? Share your results or model/engine details in the comments to help other readers. Found this helpful? Bookmark it for your next tune-up.