Your lawn mower won’t turn over, and you’re staring at a silent engine when you’ve got a yard to cut—frustrating. The good news: most “won’t turn over” problems are caused by simple issues you can fix in minutes. Quick fix first: check the safety handles and seat switch, confirm the blade control/parking brake is engaged (riding mowers), and try a fresh or fully charged battery. For pull-start mowers, switch to fresh fuel and inspect the spark plug boot connection.

If that doesn’t do it, don’t worry. This comprehensive guide walks you through the most common causes, step-by-step diagnostics, and proven fixes for both push and riding mowers. You’ll learn how to test your battery, starter, solenoid, ignition switch, safety switches, carburetor, and more—plus how to prevent this from happening again.

Common Causes of a Lawn Mower Not Turning Over

- Dead or weak battery (riding mowers) or poor charging system

- Faulty or tripped safety switches (seat, blade/clutch, brake, neutral)

- Bad starter solenoid or starter motor

- Corroded/loose battery cables or ground connections

- Blown fuse or faulty ignition switch

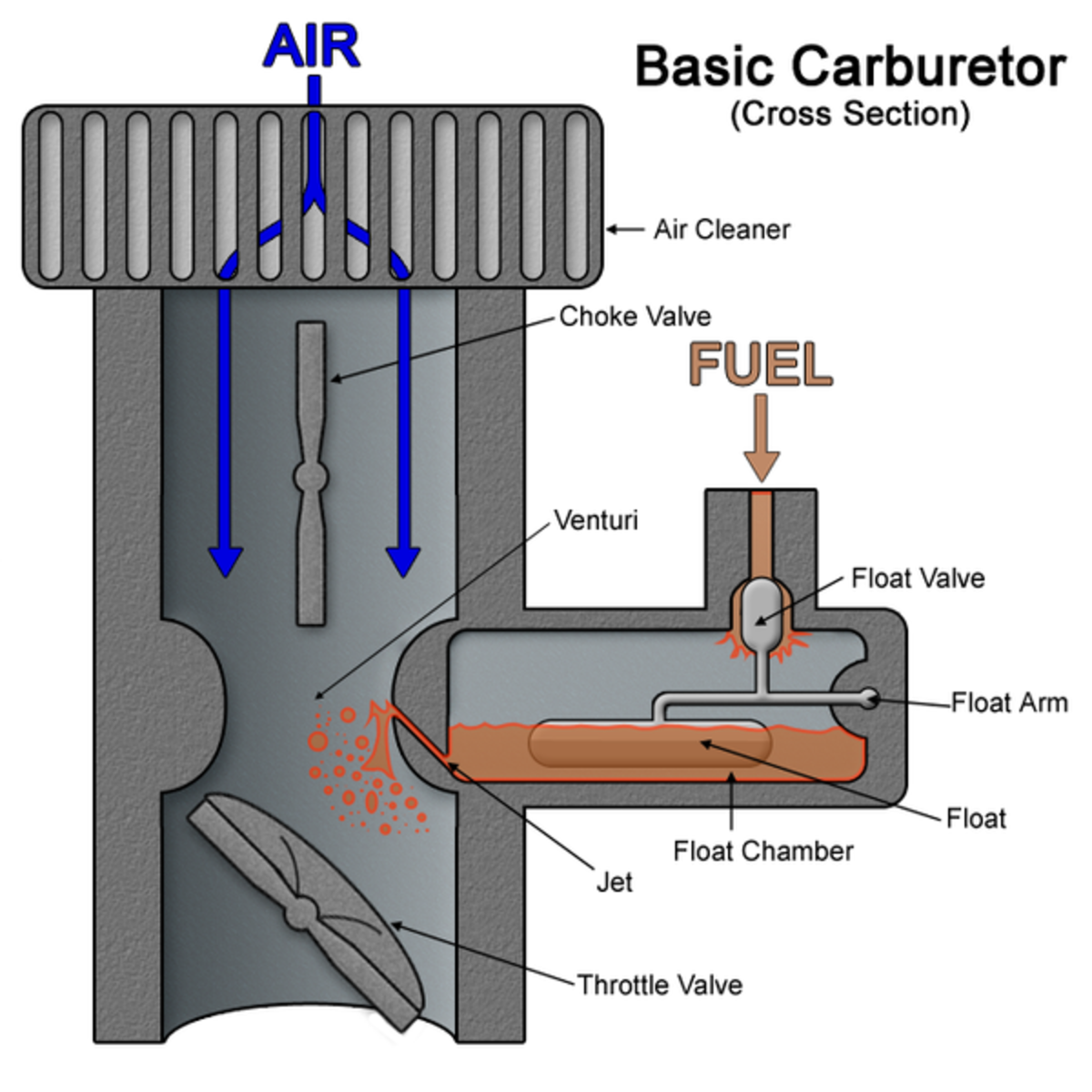

- Stale fuel, flooded engine, or gummed carburetor (pull-starts and riders)

- Hydro-lock from fuel or oil in cylinder

- Seized engine due to lack of oil or stuck piston

- Broken recoil starter (pull cord mowers)

- Clogged air filter, fouled spark plug, or bad coil

- Wrong storage position causing oil in cylinder/air filter

Important: “Won’t turn over” technically means the starter doesn’t crank the engine. If your engine cranks but won’t start, see the fuel/spark/air tips below.

How to Fix a Lawn Mower That Won’t Turn Over

Method 1: Fast Checks You Can Do in 5–10 Minutes

Diagnosing the Issue

- Does the engine make any noise when you try to start?

- No click/no crank: likely battery, fuse, ignition switch, or safety switch.

- Single/multiple clicks: likely weak battery, bad solenoid, or wiring.

- Pull-start locked tight: possible hydro-lock, stuck blade, or seized engine.

Fix Steps

1) Verify safety/controls

– Push mowers: Ensure blade control bar is fully squeezed to handle.

– Riding mowers: Sit on seat, set parking brake, shift to neutral, disengage blades (PTO off). Many models won’t crank otherwise.

2) Check battery (riders)

– Look for dim lights or clicking. If dim/clicks, charge the battery fully (12.6–12.8V fully charged).

– Use a multimeter: battery should read at least 12.4V at rest; under 10V during crank = weak battery.

– Try a known-good battery or jump-start (follow manual for safe procedure).

3) Inspect cables and grounds

– Clean corrosion from battery posts and cable ends with a wire brush.

– Ensure grounds (negative cable to frame/engine block) are tight and free of paint/rust.

4) Check fuse(s)

– Find the in-line fuse near battery/solenoid. Replace if blown (common sizes 15A–30A). If it blows again, suspect shorted wiring or a failed component.

5) Spark plug boot and air filter (pull-start and riders)

– Re-seat the spark plug boot firmly.

– Remove and tap out debris from the air filter; replace if soaked with oil or fuel.

Testing

- Try starting again. If still no crank, proceed to Method 2.

Method 2: Battery, Solenoid, and Starter Tests (Riding Mowers)

Diagnosing the Issue

- Symptoms:

- No click: ignition switch, fuse, safety switch, or open circuit.

- Clicks but no crank: weak battery, bad solenoid contacts, or starter motor.

- Strong crank then stop: seized engine or mechanical obstruction.

Fix Steps

1) Battery load test (10 minutes)

– Measure battery at rest: 12.6V is ideal. Below 12.2V needs charging.

– Measure while cranking: if it drops below 10V, battery is likely bad.

2) Solenoid test

– Listen for a click at the solenoid when turning the key.

– With multimeter: check for 12V at solenoid input from battery; check for 12V at solenoid output when key is turned.

– No output but you hear a click = bad solenoid. Replace.

– No click and input voltage present = ignition circuit/safety switches at fault.

3) Starter motor test

– If solenoid outputs 12V to the starter but no crank, the starter is likely faulty.

– Bench test the starter (remove and apply 12V safely) or swap with a known-good one if available.

4) Bypass test (for diagnosis only)

– Briefly jump the solenoid large terminals with an insulated tool to see if the starter cranks. If it cranks, the solenoid/control circuit is the issue. If it doesn’t, the starter or battery is at fault.

– Warning: Sparks possible. Wear eye protection. Only for quick diagnosis.

5) Ground and chassis checks

– Ensure engine block ground strap is intact and tight. Add a star washer for better bite if needed.

Testing

- After repairs, crank engine. If it cranks normally but won’t start, move to fuel/spark checks.

Method 3: Safety Switch and Ignition Circuit Troubleshooting

Diagnosing the Issue

- Many mowers have interlocks: seat switch, parking brake, PTO/blade switch, neutral switch, and sometimes hood switch.

Fix Steps

1) Confirm proper positions

– Seat: sit firmly. Some models won’t crank unless pressure is detected.

– PTO: off position.

– Brake: fully engaged.

– Gear: neutral.

2) Inspect switches

– Look for damaged connectors or broken tabs at the seat and brake switches.

– Test continuity with a multimeter while actuating the switch. Replace if no change.

3) Ignition switch

– Check for 12V at the B (battery) terminal.

– Turn key to Start and verify 12V at the S (start) terminal leading to solenoid coil.

– If no voltage on S, replace ignition switch.

4) Wiring harness

– Trace for chafed wires, rodent damage, or loose connectors, especially near the frame and engine.

Testing

- Try starting again. If you now have crank but no start, go to Method 4. If still no crank, revisit battery/solenoid/starter or consult a wiring diagram for your model.

Method 4: Pull-Start Mowers – Recoil and Engine Freedom

Diagnosing the Issue

- Pull cord won’t move: blade jam, hydro-lock, or seized engine.

- Pull cord retracts poorly: recoil spring issue.

Fix Steps

1) Disconnect spark plug wire for safety.

2) Check blade for obstructions

– Turn mower on its side with carburetor/air filter facing up to avoid flooding.

– Remove debris, clumps of grass, or twine.

3) Check engine freedom

– With plug removed, try rotating blade by hand (wear gloves). It should turn smoothly.

– If locked and plug removed, suspect hydro-lock.

4) Clear hydro-lock

– Remove spark plug.

– Pull starter 6–10 times to expel fuel/oil from cylinder.

– If oil came out: mower may have been tipped the wrong way. Replace air filter if oil-soaked. Reinstall plug and try again.

5) Recoil starter

– If rope won’t retract or slips, inspect the recoil assembly. Replace worn pawls or spring.

Testing

- Reconnect spark boot and test start.

Method 5: When It Cranks but Still Won’t Start (Fuel, Spark, Air)

Even if your mower now turns over, it may not fire. Use this to finish the job.

Diagnosing the Issue

- No start with starter fluid: likely no spark.

- Brief start with starter fluid: likely fuel delivery problem.

Fix Steps

1) Fuel system (15–40 minutes)

– Use fresh, ethanol-free fuel if possible. Old fuel (>30–60 days) causes hard starting.

– Replace in-line fuel filter if equipped.

– Open fuel cap to relieve vacuum (bad vent can block flow).

– Check fuel shutoff valve position.

– Clean carburetor main jet and bowl: remove bowl, clean jet with carb cleaner and a bristle, replace gasket if worn.

2) Spark system (10–20 minutes)

– Replace spark plug (proper gap typically 0.028–0.030 inches for many small engines; verify your model).

– Check ignition coil air gap to flywheel (often 0.010–0.014 inches).

– Ensure kill wire isn’t shorted to ground.

3) Air filter

– Replace severely dirty or oil-soaked paper filters.

– Clean foam pre-filters with soapy water, dry thoroughly, re-oil lightly.

4) Choke and primer

– Confirm choke plate closes fully for cold start and opens after starting.

– Ensure primer bulb isn’t cracked and lines are intact.

Testing

- Start engine. If it runs briefly then dies, recheck fuel delivery and carburetor passages.

Method 6: Mechanical Checks (If All Else Fails)

Diagnosing the Issue

- Persistent no-crank with good electricals can indicate internal problems.

Fix Steps

1) Oil level and condition

– Low or contaminated oil can cause safety shutoffs or damage. Fill to spec. If metallic glitter is present, internal wear is likely.

2) Compression check

– Use a small-engine compression gauge. Typical values >70–90 psi; under ~60 psi suggests valve or ring issues.

– For overhead valve engines, adjust valve lash per spec (common: intake/exhaust ~0.004–0.006 inches; verify model).

3) Seized or partially seized engine

– Remove spark plug and add a teaspoon of light oil. Let sit, then gently rotate the crank via blade or flywheel nut. If it won’t budge, professional service is needed.

Testing

- After adjustments, attempt start again.

How to Prevent Future No-Crank/No-Start Problems

- Keep battery on a smart maintainer during off-season; replace every 3–5 years.

- Use fresh fuel; add stabilizer if storing over 30 days.

- Store mower level; never tip carburetor/air filter down.

- Clean underside and deck; remove string or wire near blade hub.

- Service carburetor and replace filters annually.

- Inspect and clean battery terminals and ground points twice per season.

- Follow safety switch procedures every start: brake, PTO off, neutral, seated.

Pro Tips

- Label safety switch connectors as you remove them; it saves guesswork on reassembly.

- If a fuse keeps blowing, inspect the headlight harness and PTO wires—common chafe points.

- Measure charging voltage at battery with engine running: 13.5–14.5V indicates a healthy charging system.

- Keep a spare spark plug and in-line fuel filter on hand; they solve many “mystery” no-starts quickly.

- For ethanol-blend fuel, use it fresh and store with stabilizer; ethanol attracts moisture and gums jets.

- Use dielectric grease on battery terminals and ignition connectors to prevent corrosion.

- If you must tip a mower, tilt spark plug up and carburetor/air filter up to avoid flooding.

When to Call a Professional

- Repeated blown fuses, melted connectors, or smoke from wiring.

- Starter engages but grinds or free-spins (possible damaged flywheel ring gear).

- Engine seized or compression is very low.

- Persistent no-crank after confirmed good battery, solenoid, and starter.

- Valve adjustments, carb rebuilds, or governor issues you’re not comfortable doing.

What to look for:

– Technician experienced with your engine brand (Briggs & Stratton, Honda, Kohler, Kawasaki).

– Clear labor rates and diagnostic fee upfront.

– Warranty on parts and labor (typically 30–90 days).

Typical costs:

– Battery: $35–$90

– Solenoid: $15–$40

– Starter motor: $80–$200

– Carb clean/rebuild: $75–$200

– Shop diagnostic: $50–$120

Warranty notes:

– New mowers may have interlock or ignition parts covered; modifications can void coverage. Always check your manual and warranty terms before DIY electrical bypass tests.

FAQ

Q: My riding mower just clicks when I turn the key. What does that mean?

A: A clicking solenoid usually points to a weak battery, corroded connections, or a failing solenoid. Charge and load-test the battery, clean and tighten terminals and grounds, then test solenoid input/output voltage. Replace the solenoid if it clicks but doesn’t pass power to the starter.

Q: My pull-start mower’s cord is stuck. How do I free it?

A: Disconnect the spark plug, check for debris jamming the blade, and ensure the mower hasn’t been tipped incorrectly. If the cylinder is hydro-locked (fuel/oil inside), remove the plug and pull the cord several times to clear it. Reinstall the plug and try again.

Q: How do I know if my lawn mower battery is bad?

A: A healthy 12V battery reads 12.6–12.8V at rest and stays above 10V while cranking. If it drops below 10V or won’t hold a charge, it’s likely failing. Also check for corrosion or loose cables causing voltage drop.

Q: What if my mower cranks but still won’t start?

A: Focus on fuel, spark, and air. Use fresh fuel, clean or rebuild the carburetor, replace the spark plug, verify the coil produces spark, and ensure the air filter and choke are functioning.

Q: Can safety switches prevent the engine from cranking?

A: Yes. On riders, if the PTO is engaged, brake is off, or you’re not seated, most mowers won’t crank. Faulty switches or misadjusted linkages can also interrupt the start circuit.

Q: Is it safe to jump the solenoid to test the starter?

A: It’s a valid diagnostic but requires caution. Wear eye protection, keep fuel vapors away, and only touch the terminals long enough to test. If the starter spins with a jump but not via the key, suspect the solenoid or control circuit.

Q: How often should I service the mower to avoid starting issues?

A: At least annually: replace the air filter and spark plug, change oil, inspect blades and belts, and clean the carburetor bowl/jet if fuel sat. Keep the battery maintained during winter.

Alternative Solutions

If your mower is older or repeatedly unreliable, consider alternatives.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Battery electric mower | Quiet, low maintenance, instant start | Battery cost/limited run time | Small to medium yards |

| New carburetor replacement | Quick fix for fuel issues | Quality varies, tuning may be needed | Aging gas mowers with gummed carbs |

| Professional annual tune-up | Reliable performance, warranty | Costly vs DIY | Busy owners or complex riders |

| Ethanol-free fuel use | Reduces gumming, easier starts | Higher cost/availability | Seasonal or infrequent use |

Get Your Lawn Mower Working Again

Following this guide, you now have multiple solutions to fix a lawn mower that does not turn over:

– Quick safety and battery checks

– Solenoid, starter, and ignition circuit tests

– Pull-start recoil and hydro-lock fixes

– Fuel, spark, and air system steps if it cranks but won’t start

– Preventive maintenance to avoid repeat issues

Don’t let a dead mower derail your day. Work through these methods in order, and you’ll pinpoint the cause and get back to mowing fast. Still stuck? Describe your mower model and symptoms in the comments for personalized advice—and bookmark this “lawn mower does not turn over” guide for next time. You’ve got this.