Your Craftsman lawn mower won’t start, sputters, or dies after a few seconds? If it’s starved for fuel, you’re not alone. A common “no-start” culprit is that the engine isn’t getting gas. The fastest quick fix: check the fuel shutoff valve (if equipped) is ON, confirm fresh gasoline is in the tank, and prime the carburetor properly. Many mowers come back to life after a fresh fuel refill and a few primers.

If that doesn’t do it, don’t worry. This comprehensive guide covers every reason your Craftsman lawn mower isn’t getting gas—clogged carburetor, blocked fuel line, dirty filter, faulty fuel cap vent, and bad fuel pump (for some models)—plus step-by-step solutions from easiest to advanced. By the end, you’ll know exactly how to diagnose and fix fuel delivery issues and how to prevent them for good.

Common Causes of a Craftsman Lawn Mower Not Getting Gas

- Old or stale fuel (over 30–60 days) causing varnish and clogs

- Closed fuel shutoff valve or incorrect choke setting

- Clogged fuel filter or fuel line

- Dirty or gummed-up carburetor/jets

- Sticking float or faulty needle valve in carburetor

- Blocked fuel tank outlet or debris in tank

- Fuel cap vent clogged (vacuum lock)

- Faulty primer bulb, cracked lines, or air leaks

- Failing fuel pump (on some models with a pump)

- Anti-afterfire solenoid not opening (on some Briggs & Stratton engines)

How to Fix a Craftsman Lawn Mower Not Getting Gas

Follow these methods in order—from quick checks to deeper repairs.

Method 1: Quick Checks and Fresh Fuel

Diagnosing the Issue

- Symptoms: Engine cranks but won’t start, starts then dies, no fuel in carb bowl, weak smell of gas at carb.

- Tools: None (optional flashlight).

Fix Steps

- Verify fuel level and freshness.

– If gas is older than 60 days (or 30 days with ethanol), drain and replace with fresh, ethanol-free if possible (E0 or E10, 87 octane). - Check fuel shutoff valve.

– Ensure the inline valve (if present) is ON (parallel with hose). - Confirm choke and primer.

– Cold start: choke ON; prime 3–5 pushes if equipped; throttle to FAST. - Inspect the fuel cap vent.

– Loosen the cap slightly and try starting. If it runs better, the cap vent is clogged. Replace the cap or clean the vent hole. - Look for obvious leaks or kinks.

– Follow the fuel line from tank to carburetor for cracks, loose clamps, or sharp bends.

Testing

- Start the mower. If it runs, mow for 5–10 minutes.

- If it still stalls or won’t start, move to Method 2.

Method 2: Check Fuel Flow to the Carburetor

Diagnosing the Issue

- You need to confirm if fuel reaches the carburetor.

Fix Steps

- Turn OFF fuel valve (or clamp the fuel line).

- Remove the fuel line at the carb inlet.

- Place the end into a clear container.

- Turn the fuel valve ON (or unclamp).

– You should see a steady stream for at least 10–15 seconds. - If flow is weak or stops:

– Replace the inline fuel filter (arrow toward carb).

– Check the tank outlet for debris; flush tank if needed.

– Replace brittle or clogged fuel line. Use 1/4″ or 3/16″ fuel line, depending on model.

Important: Work in a ventilated area. Keep sparks and flames away. Dispose of fuel responsibly.

Testing

- Reconnect the line securely with clamps.

- Try starting again. If fuel flow is good but no start, suspect the carburetor.

Method 3: Clean the Carburetor Bowl and Jet (On-Equipment Service)

This often solves sputtering and “starts then dies” issues caused by varnish and debris.

Diagnosing the Issue

- Good fuel flow to carb but engine won’t run or only with choke.

- Draining the bowl shows dirty fuel or water droplets.

Fix Steps

- Shut off fuel valve (or clamp line).

- Place a rag under carburetor.

- Remove the bowl nut (often 1/2″ or 10mm; on many Briggs/Nikki carbs this is also the main jet).

- Remove the bowl; inspect gasket/O-ring.

- Clean parts:

– Spray carb cleaner through the bowl nut jet holes. Use a fine wire or bristle to clear tiny orifices.

– Clean inside the bowl; remove sediment and water. - Inspect float movement:

– Gently lift float; it should move freely and close the needle valve smoothly. - Reassemble:

– Refit bowl and O-ring carefully to avoid pinching.

– Tighten bowl nut snug, not overtight (about 7–9 ft-lbs if using torque). - Turn fuel ON and check for leaks.

Warning: Do not enlarge jet holes with drills or hard wire; use soft bristle or copper strand.

Testing

- Start the mower. If it runs only on choke or still dies, proceed to full carb clean.

Method 4: Full Carburetor Cleaning and Rebuild

If the mower runs only with choke or surges, the idle/main circuits are likely gummed.

Diagnosing the Issue

- Persistent no-start with verified fuel supply

- Runs only on full choke

- Surges at all speeds, especially off choke

Fix Steps

- Remove the air filter and housing.

- Disconnect linkages and springs; take photos for reference.

- Remove carburetor from engine.

- Disassemble:

– Take off bowl, float, pin, and needle.

– Remove main jet and emulsion tube (if applicable).

– Remove idle jet/mixture screw caps if accessible. - Clean thoroughly:

– Soak metal parts in carb cleaner or ultrasonic cleaner 20–30 minutes.

– Blow out all passages with compressed air.

– Ensure the emulsion tube holes are clear. - Inspect/replace parts:

– Install a carb rebuild kit specific to your Briggs & Stratton, Honda, or Kohler engine model found on Craftsman mowers. Replace gaskets, O-rings, needle, and seat if included. - Reassemble and reinstall, ensuring:

– Throttle/choke linkages are correct.

– New intake gasket is used to prevent vacuum leaks.

– Primer line (if present) is connected firmly.

Tip: Note your engine model (e.g., Briggs & Stratton 6.75 ft-lbs 190cc, Kohler XT series, Honda GCV160) to get the correct kit.

Testing

- Prime and start. Adjust idle speed to spec if needed.

- If surging persists, re-check for air leaks at the intake manifold and carb mount.

Method 5: Check the Primer System, Fuel Pump, and Solenoid

Some Craftsman mowers (especially riding mowers and some walk-behinds) include additional components.

Diagnosing the Issue

- Primer bulb doesn’t firm up or cracks: air leak, no fuel pushed to carb.

- Fuel pump (pulse or vacuum) present: poor flow even with clean lines.

- Anti-afterfire solenoid stuck shut: no fuel to main jet.

Fix Steps

- Primer bulb and lines:

– Inspect for cracks or loose fittings.

– Replace bulb and any brittle lines. Ensure the bulb’s check valves function; you should feel resistance. - Fuel pump (riders or large engines):

– Disconnect outlet line; crank engine. Look for pulsing fuel flow.

– If weak, check vacuum pulse line from engine; replace cracked lines.

– Replace the pump if diaphragm is worn. - Anti-afterfire solenoid (carb bowl base, 2-wire connector):

– Turn ignition ON; listen/feel for a click on the solenoid.

– If no click, check fuse and wiring. Test by unscrewing the solenoid and confirming the plunger retracts with 12V. Replace if faulty.

Warning: Bypass of solenoid is not recommended; it’s a safety/emissions device.

Testing

- After replacement, prime and start. Confirm steady operation at all throttle positions.

Method 6: Address the Fuel Cap Vent and Tank Debris

Diagnosing the Issue

- Mower runs briefly, then stalls; loosening cap fixes it (vacuum lock).

- Visible debris/rust flakes in tank.

Fix Steps

- Clean or replace the fuel cap.

– Caps are inexpensive; replacing is often easier and more reliable. - Drain and flush the tank.

– Remove tank if accessible. Rinse with fresh fuel; avoid water.

– Install an inline fuel filter if not already present.

Testing

- Run for 15–20 minutes. If stalling is gone, the vent/tank was the issue.

How to Prevent Future Fuel Delivery Problems

- Use fresh, top-tier gasoline. Prefer ethanol-free (E0) if available.

- Add a fuel stabilizer (e.g., Sta-Bil, Sea Foam) whenever fuel will sit 30+ days.

- Run the engine monthly for 10 minutes during the mowing off-season.

- Shut off the fuel valve and run the carb dry before long storage.

- Replace fuel filter every season or 25 hours.

- Change fuel lines every 2–3 years or at first sign of cracking.

- Keep the air filter clean; a clogged filter alters mixture and can foul the carb.

Pro Tips

- Photograph linkage and spring positions before removing the carb—saves headaches during reassembly.

- If your mower only starts with starter fluid, it’s a fuel delivery issue; don’t keep using ether—it can damage the engine. Fix the root cause instead.

- Surging at no-load is often a clogged main jet or an intake gasket vacuum leak—replace the gasket when servicing the carb.

- Use an inline shutoff valve on walk-behinds without one; it simplifies storage and service.

- Replace bowl O-rings whenever removed; reusing flattened O-rings causes leaks and air entry.

- Avoid steel wire in jets; use a copper strand from electrical wire or a nylon bristle.

- Label hoses when removing multiple lines: tank, pulse, and carb lines can be mixed up on reassembly.

When to Call a Professional

- You smell strong fuel or see persistent leaks you can’t locate.

- The carburetor body is corroded or stripped, or the throttle shaft is loose (air leak).

- You have a riding mower with complex fuel routing, a failed electronic solenoid, or electrical issues you can’t diagnose.

- Repeated failures after cleaning—likely needs a full rebuild or carb replacement.

What to look for in a shop:

– Small engine certification or brand experience (Briggs & Stratton, Kohler, Honda).

– Clear labor rates and parts estimate upfront.

– Warranty on repairs (30–90 days typical).

Typical costs:

– Fuel system clean and tune: $60–$120 (walk-behind).

– Carb rebuild/replace: $80–$180.

– Riding mower fuel pump/line service: $120–$250.

Warranty note: If your Craftsman mower is still under warranty, contact the authorized service center before performing major disassembly.

FAQ

Q: How do I know if my Craftsman mower isn’t getting gas?

A: Common signs include dry spark plug after cranking, engine only running on starter fluid, no fuel in the carb bowl, or it runs briefly and dies. Confirm by disconnecting the fuel line at the carb and checking for steady flow.

Q: Can old gas really stop my mower from starting?

A: Yes. Gasoline starts to degrade in as little as 30 days (faster with ethanol), forming varnish that clogs jets and passages. Always use fresh fuel and add stabilizer if it will sit.

Q: My mower only runs on choke—what does that mean?

A: That usually indicates a lean condition caused by a partially clogged main jet or an air leak at the intake. Clean the carburetor thoroughly and replace the intake gasket.

Q: Should I rebuild or replace the carburetor?

A: If the carb body is intact, a rebuild kit (gaskets, needle, seat) and proper cleaning often restore function. If it’s corroded, warped, or has a worn throttle shaft, replacement is more reliable and sometimes cheaper.

Q: How often should I replace the fuel filter?

A: At least once per season or every 25 operating hours. Replace sooner if you see restricted flow or find debris in the tank.

Q: What fuel is best for Craftsman mowers?

A: Use fresh 87+ octane gasoline. Ethanol-free (E0) is ideal. If using E10, add stabilizer and avoid long storage.

Q: Do Craftsman walk-behind mowers have a fuel pump?

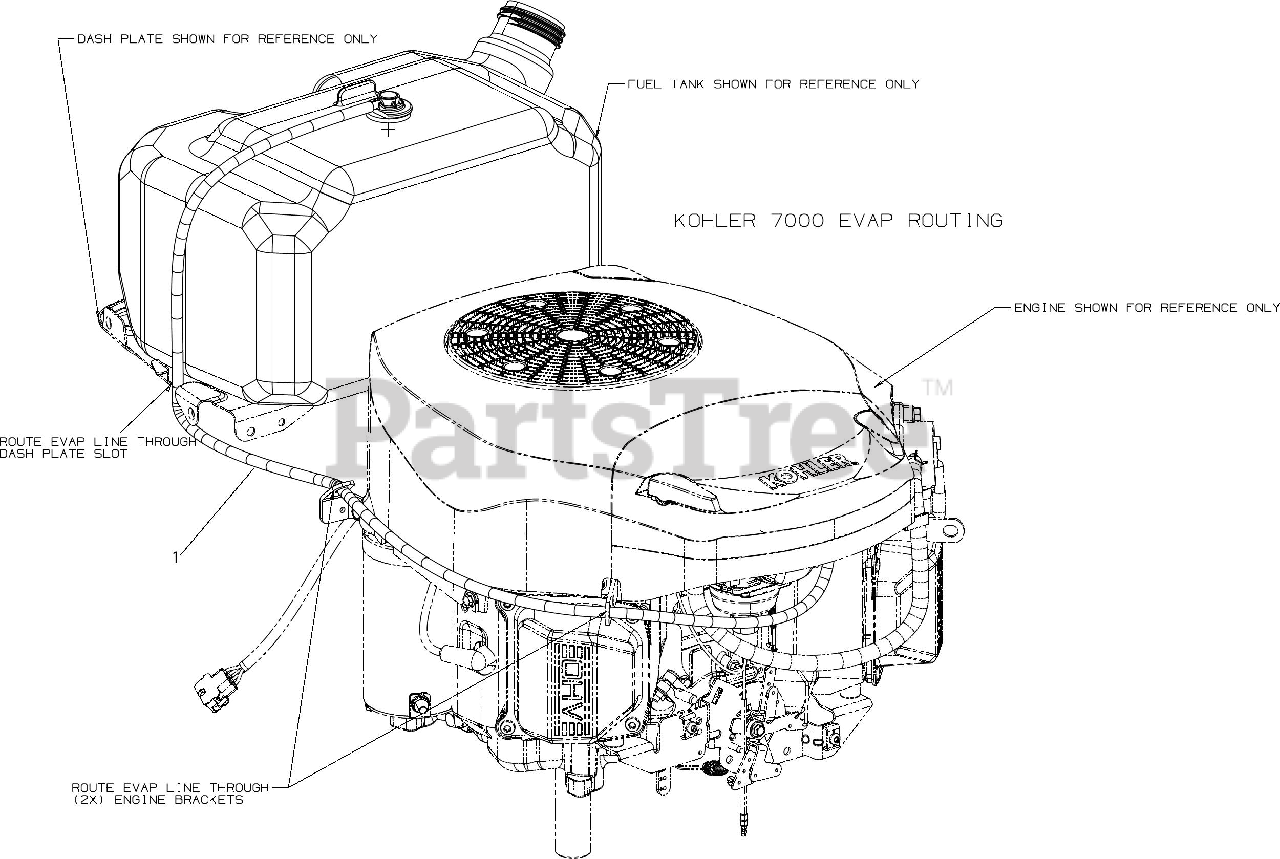

A: Most walk-behinds are gravity-fed and don’t use a pump. Riding mowers and some larger engines do. Check your model’s parts diagram.

Q: What is the anti-afterfire solenoid and can it cause no fuel?

A: It’s an electrically actuated plunger on the carb bowl that shuts fuel to prevent backfire on shutdown. If it fails closed, fuel won’t reach the main jet. Test for a click with key ON; replace if faulty.

Alternative Solutions

If repeated clogs persist or ethanol fuel is unavoidable, consider these options.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Ethanol-free fuel (E0) | Reduces varnish and phase separation; better storage | Higher cost, not always available | Seasonal users, infrequent mowing |

| Add fuel shutoff valve | Easy storage and service; run carb dry | Requires installing and remembering to use | DIYers comfortable with minor mods |

| Inline micro fuel filter upgrade | Better filtration | Slightly reduces flow if undersized; periodic replacement | Mowers with dirty tanks or older equipment |

| New replacement carburetor | Fast, reliable fix | Higher cost than cleaning; quality varies | Severely gummed or damaged carbs |

Get Your Craftsman Lawn Mower Working Again

By following this guide, you can eliminate the most common causes of a Craftsman lawn mower not getting gas:

– Quick checks: fresh fuel, correct choke, cap vent, and valve position

– Fuel delivery verification: filter, lines, and tank outlet

– Carb fixes: bowl/jet cleaning or full rebuild

– Component checks: primer bulb, fuel pump, and anti-afterfire solenoid

– Preventive steps to keep fuel flowing cleanly

Don’t let a simple fuel issue sideline your mower. Start with the easy checks, work methodically, and you’ll have your Craftsman running reliably again.

Have you fixed your mower with one of these methods? Share what worked for you below, and help other readers get back to mowing fast. Found this helpful? Bookmark it for your next tune-up.