You pull the cord or turn the key—your lawn mower cranks, but won’t fire up. Frustrating. The good news? When a lawn mower turns over but will not start, the problem is typically fuel, spark, air, or compression related—and many fixes are quick. Start with the simplest: check fresh fuel, the spark plug connection, and the air filter. Often, replacing stale gas, reseating the plug wire, or cleaning the filter gets you running in minutes.

In this comprehensive guide, you’ll get step-by-step methods to diagnose and fix a mower that cranks but won’t start. We’ll cover common causes for both gas push mowers and riding mowers, how to test for spark and fuel delivery, carburetor cleaning, choke and ignition issues, and when to call a pro. By the end, you’ll have multiple solutions to fully resolve the issue and prevent it from coming back.

Common Causes When a Lawn Mower Turns Over but Won’t Start

- Stale or contaminated fuel (older than 30–60 days)

- Clogged carburetor or jets

- Fouled or damaged spark plug

- Spark not reaching the plug (loose wire, bad coil)

- Flooded engine from excessive priming or choke misuse

- Dirty or oil-soaked air filter

- Faulty choke or auto-choke linkage

- Safety switches preventing ignition (blade/seat/brake)

- Low compression (worn rings, head gasket leak)

- Sheared flywheel key (after hitting an object)

- Weak battery or bad solenoid (riding mowers—cranks but slow or inconsistent)

- Fuel delivery issues (clogged fuel filter, kinked line, bad fuel cap vent)

How to Fix a Lawn Mower That Turns Over but Will Not Start

Method 1: Quick Checks and Easy Wins

Diagnosing the Issue

- Applies to: All gas push mowers and riding mowers.

- Time: 10–20 minutes.

Fix Steps

1) Confirm fresh fuel

– Drain old gas if it’s over 60 days or smells varnishy.

– Refill with fresh, ethanol-free (if possible) 87–91 octane.

– Add fuel stabilizer if the mower sits more than a month.

2) Check the spark plug

– Pull the plug wire boot firmly off and reseat it.

– Remove the plug with a socket. If it’s black/sooty, wet, or crusted, clean with a wire brush and check the gap (0.028–0.030 inches typical; verify your manual).

– Replace if worn, cracked, or fouled. Cost is low and often fixes no-starts.

3) Inspect the air filter

– Foam filter: wash with warm soapy water, rinse, fully dry, then lightly oil and wring out.

– Paper filter: tap gently to remove debris; replace if dark, oily, or clogged.

4) Set choke and throttle correctly

– Cold start: Full choke, half throttle; crank for up to 10 seconds.

– Warm start: No choke or half choke depending on engine.

5) Check safety interlocks

– Push mower: Blade control lever fully engaged.

– Riding mower: Sit in seat, parking brake set, PTO/blades OFF, transmission in neutral.

Testing

- Try starting after each step. If it still turns over but won’t start, move to Method 2.

Method 2: Check for Spark and Fuel Delivery

Diagnosing the Issue

- Applies to: All gas mowers.

- Time: 20–30 minutes.

- Goal: Determine if the engine lacks spark, fuel, or both.

Fix Steps

1) Test for spark

– Remove the spark plug, reconnect the wire, and hold the plug’s metal threads against bare engine metal using insulated pliers.

– Crank the engine. Look for a strong blue spark at the electrode.

– No spark? Try a new plug. Still no spark? Suspect the ignition coil or a kill switch/short in the bail cable or wiring on riders.

2) Check for flooding

– A wet plug indicates flooding. Disable choke, open throttle fully, pull cord 5–10 times (or crank for 5–10 seconds) to clear. Let it sit 10 minutes. Install a dry/new plug and try again with no choke.

3) Fuel delivery test

– Remove the air filter and spray a small shot of carb cleaner into the intake. Reinstall the filter housing cover loosely.

– Crank the engine. If it briefly fires, the issue is fuel-starvation: clogged carb jets, stuck float/needle, or blocked fuel flow.

4) Inspect fuel flow

– Turn off the fuel valve (if present). Disconnect the fuel line at the carb inlet and place the hose into a container. Open the valve. Fuel should flow steadily.

– Weak/no flow? Check/replace the inline fuel filter, ensure the fuel cap vent is clear (loosen cap as a test), and inspect for kinks or debris in the line.

Testing

- After correcting any fuel flow issues, attempt to start. If it fires only on carb cleaner, proceed to Method 3 for carburetor cleaning.

Method 3: Clean the Carburetor and Jets

Diagnosing the Issue

- Applies to: Engines that fire with carb cleaner but won’t run otherwise.

- Time: 30–60 minutes.

- Warning: Work in a ventilated area. Keep flames/sparks away.

Fix Steps

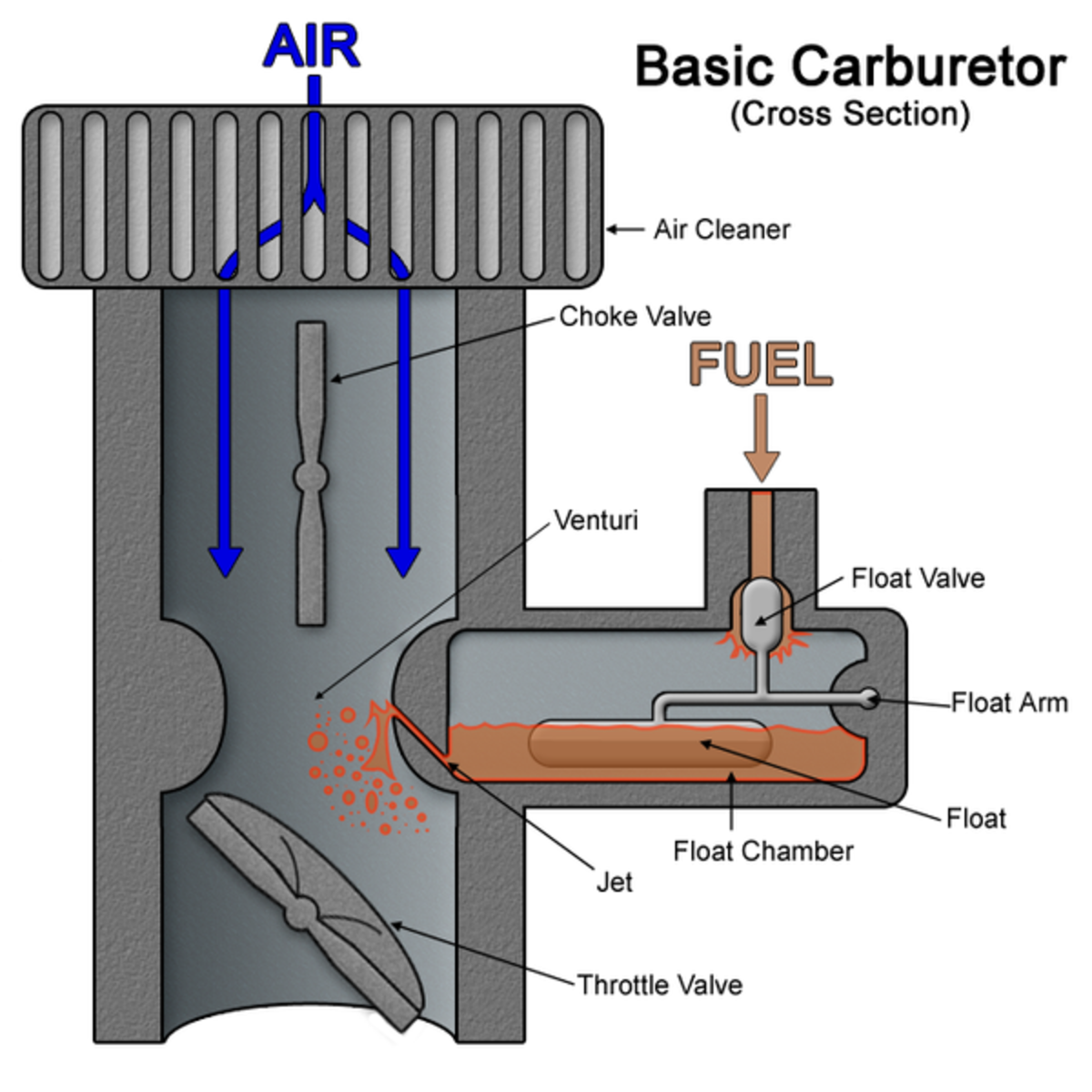

1) Remove the carburetor bowl

– Shut off fuel valve or clamp the fuel line.

– Remove the bowl nut (often also the main jet) at the bottom of the carb.

– Catch fuel in a container. Inspect the bowl for varnish or debris.

2) Clean main jet and emulsion tube

– The bowl nut jet has tiny holes—spray carb cleaner and use a soft wire or bristle (not a drill bit) to clear all orifices.

– Remove the emulsion tube (if accessible) from the carb throat and clean its side holes.

3) Free the float and needle

– Gently remove the float pin; lift float and needle. Clean needle tip and seat area with carb cleaner. Replace if the tip is grooved or swollen.

4) Reassemble with a new bowl gasket if damaged

– Ensure the float moves freely and sits level when the carb is inverted (roughly; specs vary). Reinstall the bowl and tighten snugly.

5) Consider a full rebuild

– If heavy varnish is present, remove the entire carb and soak components in carb cleaner or ultrasonic bath. Install a rebuild kit (gaskets, needle, seat, jet).

Testing

- Turn on fuel, check for leaks, prime if applicable, and start with correct choke. If it starts and dies under load, repeat jet cleaning or replace the carb (cost-effective on many small engines).

Method 4: Fix Ignition and Kill Switch Issues

Diagnosing the Issue

- Applies when there’s no spark with a good plug, or intermittent spark.

- Time: 20–45 minutes.

Fix Steps

1) Inspect coil air gap

– Remove the blower housing/shroud. Check the ignition coil gap to the flywheel magnet (typical spec: 0.010–0.014 inches; use a business card if no gauge).

– Adjust by loosening coil screws, letting the magnet pull the coil to the card, then retighten and remove the card.

2) Check kill wire and switches

– The thin wire from the coil goes to a stop switch/bail cable or to a safety module on riders. Any short to ground will kill spark.

– Disconnect the kill wire at the coil and test for spark again. If spark returns, trace faulty switch or chafed wiring.

3) Replace the ignition coil if needed

– If there’s still no spark with the kill wire disconnected and a known-good plug, install a new coil.

Testing

- Reassemble and test. Confirm consistent blue spark and reliable starting.

Method 5: Air and Choke System Corrections

Diagnosing the Issue

- Applies when the mower only starts on partial choke or surges.

- Time: 15–30 minutes.

Fix Steps

1) Replace a clogged air filter

– Especially after dusty mowing. An oil-soaked filter severely enriches mixture and prevents starting.

2) Verify choke plate movement

– Move the choke lever and watch the choke plate in the carb throat. It should fully close for cold start and open when running. Fix bent linkages or sticky auto-choke thermostats.

3) Check primer bulb and line

– Cracked bulbs or loose lines won’t deliver fuel. Replace if bulb is brittle or doesn’t rebound.

Testing

- Start cold on full choke; open choke within a few seconds of firing to prevent flooding.

Method 6: Compression, Timing, and Mechanical Issues

Diagnosing the Issue

- Applies if all else checks out. Common after hitting a rock or root.

- Time: 30–60 minutes.

Fix Steps

1) Compression check (optional but helpful)

– Use a compression gauge. Small engines often show 70–120 psi with compression release systems; consult engine manual. Very low compression indicates valve or ring issues.

2) Inspect flywheel key

– Remove the flywheel nut and check the soft key in the crank/flywheel slot. A partially sheared key throws off ignition timing and causes crank-no-start.

– Replace with the correct key; do not substitute with hard steel.

3) Valve clearance (OHV engines)

– If valves are too tight, hot or cold starts fail. Remove the valve cover, rotate to compression stroke, and set lash to spec (e.g., 0.004–0.006″ intake/exhaust—check your engine label/manual). Replace cover gasket if needed.

4) Head gasket

– Blown gasket between cylinder and pushrod area can cause low compression and misting around the head. Replace if leaking.

Testing

- After timing/valve corrections, start the engine and listen for smooth idle and throttle response.

How to Prevent Future No-Start Problems

- Use fresh, stabilized fuel; avoid E10 where possible or run stabilizer year-round.

- Run the carb dry before seasonal storage: turn off fuel valve and let it stall.

- Replace spark plug every season or 100 hours.

- Clean/replace air filter every 25 hours (more often in dust).

- Service carb yearly if ethanol fuel is used frequently.

- Keep blades sharp and deck clean to reduce engine load and flooding from tipping.

- Store the mower level; avoid tipping carburetor-side to prevent oil in the filter.

Pro Tips

- If the mower only runs with the gas cap loosened, the cap vent is clogged—replace the cap.

- Surging or “hunting” at idle usually signals a partially clogged main jet—clean or replace.

- For stubborn varnish, a full carb swap is often quicker and inexpensive on common models (Briggs & Stratton, Honda GCV, Kohler).

- Use a spark tester inline tool for a hands-free, accurate spark check.

- Never over-prime; 2–3 primes are enough on most engines. Too much floods the cylinder.

- On riders, a weak battery may crank fast initially but drop voltage below ignition needs. Load-test battery or measure while cranking (stay above ~9.6V).

- Keep a maintenance log; small adjustments like valve lash can drift over seasons.

When to Call a Professional

- No spark after replacing plug and coil and verifying kill circuits.

- Low compression confirmed or persistent backfiring/kickback.

- Repeated sheared flywheel keys or unknown internal noises.

- Carburetor repeatedly clogs despite fresh fuel and filter (possible tank contamination).

- Valve or head gasket work you’re not comfortable performing.

What to look for in a service provider

– Small engine certification, good reviews, clear labor rates, and parts availability.

– Ask for a diagnostic estimate and turnaround time.

Typical cost ranges

– Carb clean/rebuild: $60–$120

– New carb: $50–$150 installed (model dependent)

– Ignition coil: $60–$120 installed

– Valve adjustment: $80–$150

– Head gasket/major work: $150–$300+

Warranty considerations

– Newer mowers may have 2–3 year warranties; modifications or stale fuel damage may not be covered. Keep receipts and maintenance records.

FAQ

Q: My lawn mower turns over but will not start after winter. What should I check first?

A: Start by draining old fuel and refilling with fresh gas, replace or clean the spark plug, and clean/replace the air filter. Most post-storage no-starts are stale fuel or clogged jets—try carb cleaner into the intake to test for fuel starvation.

Q: The engine only fires when I spray carb cleaner. What does that mean?

A: It indicates a fuel delivery issue—typically a clogged main jet, stuck float/needle, or blocked fuel line/filter. Clean the carb bowl and jet, verify fuel flow, and check the gas cap vent.

Q: How do I know if my mower is flooded?

A: A strong fuel smell and a wet spark plug are giveaways. Open the throttle, turn off choke, pull-start several times to clear, wait 10 minutes, install a dry plug, and retry with minimal choke.

Q: Can a bad spark plug cause cranking without starting?

A: Yes. A fouled, cracked, or improperly gapped plug can prevent ignition. Replace the plug first—it’s quick and cheap.

Q: My riding mower cranks but won’t start—could it be a safety switch?

A: Absolutely. Seat, brake, and PTO switches can cut ignition or fuel solenoid power. Ensure you’re seated, brake set, blades off, and test/replace faulty switches if necessary.

Q: Do I need to clean or replace the carburetor?

A: If it briefly runs on carb cleaner or the jet is visibly varnished, clean the bowl and jets. If issues persist or corrosion is severe, a replacement carb is often faster and cost-effective.

Q: After hitting a rock, the mower cranks but backfires and won’t start. Why?

A: Likely a sheared flywheel key that shifted ignition timing. Replace the key with the correct soft-key part and retorque the flywheel nut to spec.

Q: Should I use fuel stabilizer all season?

A: Yes, especially with ethanol fuels. Stabilizer reduces varnish, moisture, and phase separation—major causes of no-starts.

Alternative Solutions

If repeated carb issues persist or the mower is aging, consider alternatives.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace carburetor | Fast, reliable fix; cleans slate | Slightly higher parts cost | Common engines with cheap carbs |

| Switch to ethanol-free fuel | Reduces varnish and corrosion | Higher price, limited availability | Seasonal or infrequent use |

| Battery-electric mower | No fuel/carb issues, low maintenance | Higher upfront cost, battery life limits | Small to medium lawns, light users |

| Annual professional tune-up | Prevents downtime, extends life | Recurring cost | Users wanting worry-free operation |

Get Your Lawn Mower Working Again

Follow these steps in order and you’ll solve most “lawn mower turns over but will not start” issues:

– Refresh fuel, check plug, and clean/replace the air filter

– Verify spark and clear flooding

– Ensure solid fuel flow; clean carb bowl, jets, and float/needle

– Inspect choke operation and safety interlocks

– Address ignition coil, timing (flywheel key), and valve clearance if needed

Tackle the quick fixes first—many mowers spring back to life with fresh gas and a new spark plug. With the right checks, you can get back to mowing today and prevent future starting problems.

Still stuck? Describe your mower model and symptoms in the comments for personalized advice. Found this helpful? Bookmark this guide for next season. You’ve got this—the no-start frustration ends here.