You pull your mower’s cord and it stays limp—or worse, it barely retracts and jams. Frustrating, right? If your lawn mower starter rope is not retracting, the quickest fix is often a simple reset: remove the starter housing, clean out debris, and re-tension the recoil spring by rotating the pulley 4–6 turns before feeding the rope back in. This takes about 20–30 minutes and requires only basic tools.

In this guide, you’ll learn every common cause and how to fix each one—step-by-step. We’ll cover jammed pulleys, frayed cords, weak recoil springs, misaligned pawls, and even flooded engines that mimic a stuck recoil. By the end, you’ll have a smooth, snappy pull cord again and know how to prevent it from sticking in the future.

Common Causes of a Lawn Mower Starter Rope Not Retracting

- Rope tangled on the pulley: The rope can jump grooves or overlap, stopping retraction.

- Dirt and grass packed in the recoil housing: Debris increases friction and jams the pulley.

- Weak or broken recoil (return) spring: The spring loses tension or snaps with age.

- Frayed or swollen starter rope: A worn rope drags in the pulley or starter handle.

- Damaged or sticky pulley: Cracks or burrs prevent smooth movement.

- Stuck pawls (starter dogs): Pawls may be gummed up and remain engaged with the flywheel cup.

- Engine hydrolock or compression lock: Fuel or oil in the cylinder, or excessive compression, makes the rope hard to pull and may stop retraction.

- Misaligned or loose starter housing: The recoil cover is skewed, rubbing on the pulley.

- Faulty starter handle or rope knot: The handle knot is too big or jammed, restricting return.

- Rust or lack of lubrication: Dry components increase resistance.

How to Fix a Lawn Mower Starter Rope Not Retracting

Important: Always disconnect the spark plug wire before working on the starter to prevent accidental starting.

Method 1: Quick Clean, Reset, and Retension (Most Common Fix)

Time: 20–30 minutes

Tools: Phillips/flathead screwdriver, socket set, needle-nose pliers, rag, light machine oil or dry PTFE lubricant

Diagnosing the Issue

- Pull the rope gently several times. If it retracts slowly or not at all, you likely have a debris jam or lost spring tension.

- Listen for scraping or grinding—indicates debris or rubbing.

- Check if the rope is frayed or swollen at any point.

Fix Steps

1) Disconnect power

– Remove the spark plug boot. If you have a battery-start mower with a cord too, disconnect the battery.

2) Remove the starter housing

– Typically 3–6 screws on the top shroud. Lift the recoil assembly off carefully.

3) Inspect and clean

– Blow out or brush away grass, dirt, and twigs from the housing, pulley, and pawls.

– Wipe the pulley groove and rope path with a dry rag.

4) Check rope path

– Ensure the rope sits properly in the pulley groove without overlaps.

– If tangled, use pliers to gently untangle and rewind evenly.

5) Lubricate friction points

– Apply a small amount of dry PTFE or silicone spray to the pulley shaft, pawl pivots, and recoil spring hub (avoid soaking). Avoid heavy grease—it attracts dirt.

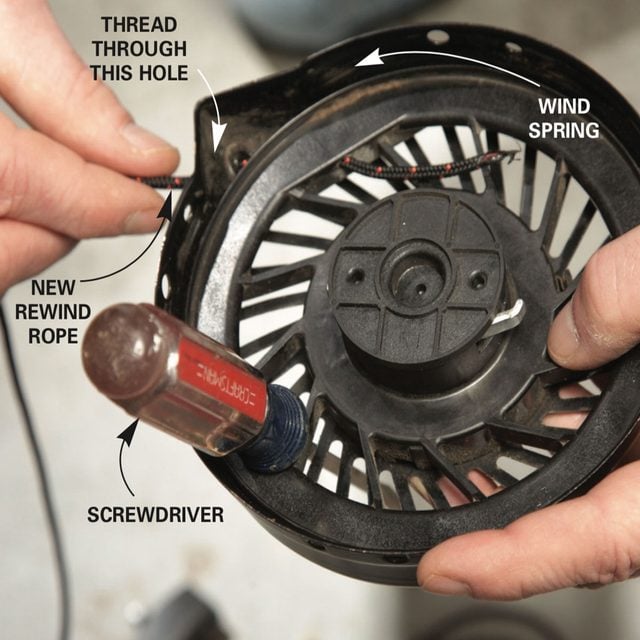

6) Retension the recoil spring

– Hold the pulley and rotate it in the direction that would wind the rope in (usually clockwise when viewed from the front) 4–6 full turns. You’ll feel spring resistance.

– Align the pulley hole with the housing eyelet.

– Insert a screwdriver through the pulley and housing to hold position if needed.

7) Reset the rope

– If rope is fully extended: thread it through the housing eyelet and into the pulley hole. Tie a firm figure-eight knot inside the pulley. Reinstall handle with a secure overhand knot.

– If rope is partly in: unhook the handle briefly, feed slack back through, then let the pulley slowly retract the rope while you guide it.

8) Test recoil

– Let go of the rope. It should snap back smoothly without slapping. If weak, add 1–2 more pulley turns for additional tension.

Testing

- Reinstall the housing and reconnect the spark plug.

- Pull several times. If it retracts crisply, you’re done. If it still hangs, proceed to Method 2.

Method 2: Replace a Frayed Rope and Handle

Time: 20–40 minutes

Tools: Scissors/utility knife, lighter, pliers, new starter rope (typically 3.0–3.5 mm or 1/8–9/64 in; check your model), new handle if worn

Diagnosing the Issue

- Rope looks fuzzy, stiff, swollen, or has flat spots.

- Rope binds in the eyelet or pulley and retracts slowly.

Fix Steps

1) Remove housing and unload spring tension

– Follow steps in Method 1 to remove the housing.

– Allow the pulley to unwind fully to remove tension.

2) Remove old rope

– Pull the knot from the pulley center with pliers and remove rope.

– Remove rope from handle.

3) Prepare the new rope

– Cut to length: walk-behind mowers typically need 6–9 feet (1.8–2.7 m). Measure old rope or consult manual.

– Melt ends lightly with a lighter and pinch to form a tapered tip to prevent fraying.

4) Thread the new rope

– Thread rope through the housing eyelet first, then into the pulley hole from outside to inside.

– Tie a secure figure-eight or double overhand knot inside the pulley. Seat the knot flush.

5) Preload and install handle

– Preload spring by rotating the pulley 4–6 turns in the winding direction.

– Feed rope through the handle and tie a double overhand knot. Trim excess and melt the tail.

6) Guide retraction

– Slowly release the pulley, allowing it to pull the rope in. Ensure smooth, even winding.

Testing

- Confirm snap-back. If weak, re-tension 1–2 more turns. If the pulley stops before full retraction, you may have too-short rope or too little tension.

Method 3: Free Stuck Pawls and Service the Pulley

Time: 25–45 minutes

Tools: Screwdrivers, small wire brush, cotton swabs, dry PTFE/silicone lube

Diagnosing the Issue

- Rope pulls out but doesn’t retract until you jiggle or tap the housing.

- You hear clicking, but the rope feels “grabby.”

- The starter pawls (dogs) remain extended after a pull.

Fix Steps

1) Access pawls

– Remove the starter housing. Look at the top of the flywheel cup and the pawls on the recoil unit.

2) Clean and free movement

– Brush away debris on pawl pivots and the flywheel cup.

– If pawls are sticky, clean with isopropyl alcohol. Do not over-lubricate; a tiny drop of dry lube is sufficient. Oil can attract dirt and cause sticking.

3) Inspect pulley

– Look for cracks, warped edges, or burrs along the groove. Lightly sand burrs with fine sandpaper (400–600 grit).

– Replace the pulley if cracked or misshapen.

4) Reassemble and tension

– Reassemble, preload spring, and test retraction.

Testing

- Pull briskly; pawls should extend and retract smoothly. If pawls still stick, consider replacing the pawl assembly.

Method 4: Replace or Re-Seat the Recoil Spring

Time: 30–60 minutes (advanced)

Tools: Needle-nose pliers, gloves, safety glasses, replacement recoil spring (model-specific), small flat screwdriver

Warning: The recoil spring is under tension and can snap out. Wear eye protection and gloves.

Diagnosing the Issue

- Rope retracts weakly even after retensioning.

- You hear scraping or feel no spring resistance when winding.

- Spring is visibly broken or unhooked from the hub.

Fix Steps

1) Remove the recoil assembly

– Take off the starter housing and pulley.

2) Access the spring

– Many models have a spring cassette. If so, remove the cassette carefully. If the spring is loose, proceed gently—do not let it whip out.

3) Re-seat or replace

– If the spring hook is off the tang, re-seat both ends (inner to pulley hub, outer to housing tab).

– If cracked, kinked, or rusty, replace with a new spring or full recoil assembly.

4) Reinstall the pulley and preload

– Refit the pulley, ensure the spring engages, then preload 4–7 turns depending on model until the rope retracts fully without overstretching.

5) Secure and test

– Reassemble and test multiple pulls for consistent tension.

Testing

- Rope should return with energy but not slam the handle. If it slams, back off 1 turn of preload.

Method 5: Clear Engine Hydrolock/Compression Lock (When Rope Won’t Pull or Rewind)

Time: 10–15 minutes

Tools: Spark plug wrench, shop towel

Diagnosing the Issue

- Rope is difficult to pull or won’t extend, and then does not retract because it’s stuck extended.

- This often happens after tipping the mower on its side or after storage.

Fix Steps

1) Remove the spark plug

– Disconnect the plug boot and remove the spark plug.

2) Clear the cylinder

– Pull the starter rope several times. Fuel/oil mist may spray—cover the hole with a rag.

– If a lot of liquid ejects, let it drain for a few minutes.

3) Dry the plug and reassemble

– Clean or replace the plug if fouled. Reinstall and reconnect.

4) Test pull

– Rope should now pull and retract normally. If it does, change the air filter if soaked with oil.

Testing

- Start the mower. Expect brief smoke if oil entered the cylinder.

How to Prevent Future Starter Rope Retraction Issues

- Keep the recoil area clean: Blow out debris after every few mows.

- Use the correct rope size: Typically 3–3.5 mm (No. 4–4.5) for walk-behind mowers—check your manual.

- Avoid side tipping: If you must tip, carburetor side up to prevent oil flooding.

- Lubricate lightly: Use dry PTFE or silicone on pawls and pulley pivots every season.

- Replace worn parts promptly: Frayed rope or sluggish spring will only get worse.

- Don’t “snap” the handle: Guide it back to reduce shock on the spring and rope.

- Store indoors: Moisture causes rust and spring fatigue.

Pro Tips

- Mark preload direction: Before disassembly, add a Sharpie arrow on the pulley showing wind direction.

- Heat-shrink the handle knot: A short piece over the knot reduces snagging and premature wear.

- Use starter rope with a polyester sheath: More abrasion-resistant than plain nylon.

- Replace the entire recoil assembly if multiple parts are worn: Often cheaper and faster than piecemeal fixes.

- Check the flywheel cup: If it’s dented or burred, pawls won’t engage/disengage smoothly—file lightly or replace.

- Don’t over-lube: Oil collects dust; choose dry lubricants and use sparingly.

- Keep a spare rope pre-cut: Saves time later and encourages prompt replacement when fraying starts.

When to Call a Professional

- The recoil spring keeps popping out or won’t seat: Indicates a damaged housing or incorrect part.

- Pulley or housing is cracked and model-specific parts are hard to source.

- The rope won’t pull because the engine seized or the blade adapter is bent after hitting an object.

- Persistent hydrolock symptoms: Oil or fuel system issues may be ongoing.

- You’re uncomfortable handling spring-loaded parts.

What to look for in a service provider:

– Experience with your engine brand (Briggs & Stratton, Honda, Kohler, Toro).

– Clear labor rates and parts sourcing.

– Warranty on parts and labor (30–90 days common).

Typical costs:

– Rope and handle replacement: $30–$70.

– Recoil spring or full assembly replacement: $60–$140.

– Deep engine diagnosis (seizure/compression issues): $90–$250+ depending on damage.

Warranty considerations:

– Newer mowers may have coverage for defective recoil assemblies. Check your manual and keep receipts. Modifying parts can void coverage—follow OEM procedures.

FAQ

Q: Why does my mower starter rope pull out but return slowly?

A: The recoil spring may have lost tension, the rope might be frayed and dragging, or debris is adding friction. Clean the housing, inspect the rope, and add 1–2 extra preload turns to the spring.

Q: What size rope do I need for my lawn mower?

A: Most walk-behind mowers use 3–3.5 mm (1/8–9/64 in) rope, length 6–9 ft. Check your owner’s manual or match the diameter of the original rope.

Q: Can I lubricate the recoil spring?

A: Use very light dry PTFE or silicone spray if needed, applied sparingly. Avoid heavy oils and grease; they attract dirt and can cause sticking or spring slip.

Q: My rope won’t pull at all—did the starter break?

A: Not necessarily. You may have engine hydrolock from oil/fuel in the cylinder, especially after tipping. Remove the spark plug and pull to clear. If still jammed, check for seized engine or blade obstruction.

Q: How many turns should I wind the recoil spring?

A: Typically 4–7 full turns depending on model and rope length. Wind until the rope retracts fully with a crisp snap, without slamming the handle. Too much tension can break the spring.

Q: The handle slams into the housing—what’s wrong?

A: Over-tensioned spring or too-short rope. Back off one preload turn or install the correct length rope.

Q: Can I replace just the spring or should I buy a full recoil assembly?

A: If the housing and pulley are in good condition, a spring-only replacement is economical. If multiple parts are worn or the cassette is damaged, a complete assembly is faster and often similar in cost.

Q: Is it safe to work on the recoil spring?

A: Yes, with precautions. Wear safety glasses and gloves, and control the spring at all times. If it uncoils violently or won’t seat, stop and consider professional help.

Alternative Solutions

Sometimes, replacing the entire recoil starter assembly is the most efficient path, especially on older mowers or models with tricky springs.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace rope only | Cheapest; quick | Doesn’t fix weak spring | Good condition recoil |

| Replace spring | Restores snap; low cost | Trickier install; safety risk | Worn spring, good pulley |

| Replace full recoil assembly | Fast, comprehensive fix | Higher part cost | Multiple worn parts or time-saving |

| Professional service | No DIY risk; warranty | Labor cost | Users uncomfortable with springs |

Get Your Lawn Mower Working Again

Following this guide, you now have multiple solutions to fix your starter rope not retracting:

– Quick clean and spring retension

– Rope and handle replacement

– Pawl and pulley service

– Recoil spring repair or full assembly replacement

– Hydrolock clearing and prevention

Don’t let a stuck cord delay your yard work. Try the methods in order—most issues resolve with cleaning and retensioning in under 30 minutes. With proper maintenance, your lawn mower starter rope will retract smoothly for seasons to come.

Have you fixed your lawn mower starter rope not retracting? Share what worked for you or any questions you have—we’re here to help!