Your Craftsman snow blower sits silent when you need it most. Fresh snow blankets your driveway, temperatures drop below freezing, and the engine won’t turn over. This common winter nightmare affects thousands of homeowners annually, but most starting issues stem from just five key systems. With the right diagnostic approach, you can identify and fix the problem within an hour, getting your snow removal equipment back in action before the next storm hits. Understanding the specific failure points in your Craftsman model means you’ll spend less time troubleshooting and more time clearing your driveway.

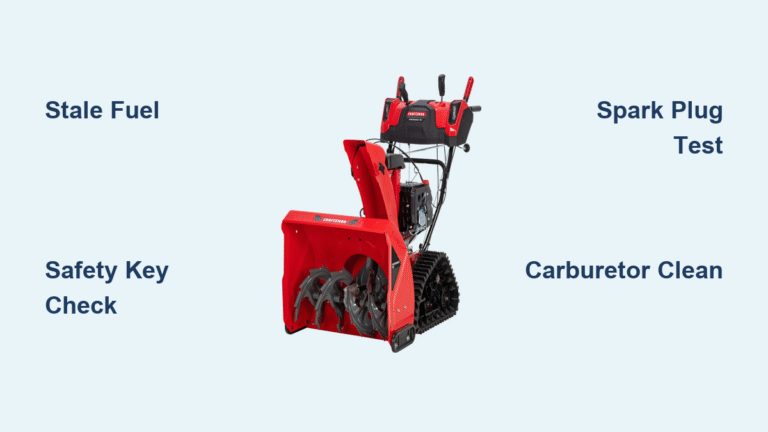

Immediate Checks That Solve Most Craftsman Snow Blower Starting Failures

Before diving into complex repairs, eliminate the simplest causes first. These quick checks take under 10 minutes and resolve starting issues in 40% of cases. Grab your basic toolkit and work through these steps systematically.

Confirm Your Fuel Isn’t the Culprit

Stale fuel causes more starting failures than any other single issue. Smell your fuel tank—if it reeks of varnish or smells sour, drain the old gasoline completely. Degraded fuel leaves sticky residue that clogs critical passages as lighter ingredients evaporate over time. Always add fuel stabilizer to fresh gasoline before storage and run the engine for five minutes to circulate treated fuel through the entire system. Never use fuel older than 30 days in your snow blower.

Test Safety Mechanisms That Block Engine Startup

Your Craftsman snow blower has multiple safety features that prevent operation when compromised. Verify the safety key is fully inserted—many models won’t start without this key properly seated. Check that the choke lever moves smoothly between positions without sticking. Ensure the fuel shutoff valve remains open during startup attempts. Some newer models have additional safety sensors that require both handles to be fully engaged before the engine will start.

Inspect Basic Electrical Connections

Loose or damaged connections create frustrating no-start conditions that take seconds to fix. Pull the spark plug wire boot straight off the plug and reconnect firmly. Check for frayed wires near sharp edges where vibration causes damage over time. Examine the kill switch connection—many models have a wire that grounds the ignition system when disconnected. These simple connection issues often mimic more serious mechanical failures.

How to Diagnose and Fix Your Craftsman’s Spark Plug System

Remove and Evaluate Your Spark Plug Condition

Proper spark plug inspection reveals critical engine health information. Use a spark plug socket to remove the plug completely from your Craftsman snow blower. Examine the porcelain insulator for cracks—any visible damage requires immediate replacement. Check the electrodes for heavy carbon buildup or burn damage that prevents proper spark generation. A wet, black tip indicates engine flooding, while a white, blistered appearance suggests overheating issues.

Verify Strong Spark Production

Reconnect the spark plug to its wire while holding the metal threads against the engine block. Have someone pull the starter rope while you watch the electrode gap. A healthy ignition system produces a bright blue spark that jumps the gap consistently with each pull. Yellow or orange sparks indicate weak ignition that won’t reliably start your engine in cold conditions. Use a spark plug tester for more accurate diagnosis if visual inspection proves inconclusive.

Install Correct Replacement Spark Plugs

Replace spark plugs annually before winter storage for reliable cold-weather starting. Gap new plugs to 0.030 inches using a feeler gauge—improper gap causes weak spark and hard starting. Hand-tighten the plug plus one-quarter turn to prevent thread damage. Never over-tighten, as this can crack the porcelain insulator or damage cylinder head threads. Keep a spare plug in your snow blower storage area for emergency replacements during heavy snow seasons.

Step-by-Step Carburetor Cleaning for Craftsman Snow Blowers

Identify Carburetor-Specific Starting Problems

Clogged carburetors cause 60% of persistent starting failures. Your Craftsman snow blower might start briefly then die, or refuse to start despite strong spark and fresh fuel. Remove the air filter and spray starting fluid into the carburetor throat—if the engine fires momentarily, carburetor issues are confirmed. Fuel left in the system during storage evaporates, leaving thicker, stickier residue that blocks tiny fuel passages essential for proper operation.

Perform Effective Carburetor Cleaning

Remove the carburetor bowl by unscrewing the bottom mounting bolt. Drain all old fuel into a container—never pour back into your gas can. Spray carburetor cleaner through all visible jets and passages, paying special attention to the main jet where clogs most frequently occur. Use compressed air to blow out debris from every direction. Let the cleaner soak for 15 minutes on stubborn deposits before attempting to blow them out—this dissolves varnish buildup more effectively.

Decide Between Rebuild and Replacement

When initial cleaning fails, purchase a carburetor rebuild kit specific to your Craftsman model number. Rebuilding takes 30-45 minutes and costs under $20 but requires careful attention to small parts orientation. Complete carburetor replacement becomes necessary when internal passages remain clogged after thorough cleaning or if housing damage exists. Check your model number before purchasing parts—Craftsman used multiple engine manufacturers over the years, requiring different carburetor configurations.

Fixing Flywheel Key Failures in Craftsman Snow Blowers

Recognize Flywheel Key Damage Symptoms

A sheared flywheel key causes immediate starting failure. This small metal component fits into the crankshaft and engages with the flywheel system. Designed as a safety mechanism, it shears in half when your snow blower strikes hard objects like hidden rocks or thick ice. Unlike other failures, a broken flywheel key often occurs suddenly during operation rather than developing gradually.

Properly Access and Replace the Flywheel Key

Remove the blower housing by taking out 3-4 mounting bolts to access the flywheel assembly. Mark the flywheel position relative to the crankshaft before removal using a permanent marker—this ensures proper reassembly timing. Inspect the flywheel key slot for both pieces of the broken key. Install a new key by sliding it fully into the crankshaft slot before reinstalling the flywheel. Never reuse a damaged key, as timing issues will persist and cause further damage.

Ignition Coil Testing and Replacement Procedures

Confirm Ignition Coil Functionality

After verifying your spark plug works correctly, test the ignition coil next. A defective coil delivers inconsistent voltage that prevents reliable starting, especially in cold weather. Connect an ignition coil tester between the spark plug wire and the plug itself. Pull the starter rope while observing the tester’s indicator light—no light or weak flashing signals coil replacement is needed. Coil failure becomes more common in snow blowers older than five years due to weather exposure.

Install New Ignition Coil Correctly

Remove the blower housing to access the ignition coil mounting area. Disconnect the kill wire before removing the two mounting screws securing the coil. Maintain proper air gap—typically 0.010 inches—between the coil and flywheel magnets during installation. This precise spacing ensures optimal voltage generation. Reconnect all wires securely and test operation before reinstalling housing covers. Keep your old coil as a backup—it might work intermittently during emergencies.

Recoil Starter Repair Solutions for Craftsman Models

Diagnose Recoil Starter Malfunctions

Broken recoil springs prevent rope retraction onto the pulley, leaving you with a tangled mess of rope. If the pull cord feels loose with no resistance or won’t retract after starting attempts, the recoil mechanism needs attention. Some models exhibit partial failure where the rope retracts slowly or sticks midway through its travel. These symptoms indicate worn components that will fail completely if not addressed.

Complete Recoil Starter Replacement

Many mechanics prefer replacing the entire recoil starter assembly rather than individual springs. Complete assemblies cost $25-40 but install in under 15 minutes with basic tools. Remove the starter assembly by taking out 3-4 mounting screws. Transfer the pull cord to the new assembly following your model’s specific winding pattern. This approach guarantees reliable operation without the frustration of spring-winding complications and saves time during winter emergencies.

Prevent Future Craftsman Snow Blower Starting Issues

Implement Proper Fuel System Maintenance

Empty the fuel tank completely before summer storage to prevent carburetor clogs. Run the engine until it stalls to clear carburetor passages of residual fuel. Add fuel stabilizer to fresh gasoline and run the engine for 5 minutes to treat the entire fuel system. Store your Craftsman snow blower in a dry, protected area away from moisture that causes electrical connections to corrode.

Schedule Seasonal Preparation Tasks

Replace the spark plug, air filter, and fuel filter every fall before first use. These inexpensive parts prevent most winter starting issues and cost less than an hour of professional service. Keep spare spark plugs and safety keys in your snow blower storage area. Test your machine monthly during storage months by starting it briefly—this keeps fuel systems clear and identifies potential problems before winter weather arrives.

Document Your Repair History

Keep a small notebook in your snow blower storage area to document repairs and part replacements. Note the date, problem symptoms, and specific parts used. This record helps identify recurring issues and simplifies future troubleshooting. When contacting customer support, having this maintenance history provides valuable context for more effective assistance.

By following this systematic approach, you’ll resolve 90% of Craftsman snow blower starting problems without professional help. Understanding your machine’s specific failure points transforms frustrating winter mornings into quick repair sessions. The next time snow falls, your Craftsman will start reliably, clearing your driveway while neighbors struggle with their uncooperative equipment. Remember that regular maintenance prevents most starting issues—spending 30 minutes each fall preparing your snow blower saves hours of emergency repairs during winter storms.