Grinding noises, failing spindles, and seized wheels usually come down to one culprit: using the wrong grease. If you’re mowing in summer heat, cutting wet grass, or running a zero-turn mower at high speeds, standard lubricants can thin out, wash away, or fail under pressure—leading to premature bearing wear and expensive repairs. You need a grease that can handle extreme conditions and protect your investment over the long term.

The right solution combines lithium complex thickeners, EP additives, and GC-LB certification for superior durability. Look for NLGI #2 consistency, which offers the ideal balance of pumpability and staying power in spindle and wheel bearings. High-performance options like Red & Tacky grease excel under heavy loads and high heat, while blue lithium grease delivers reliable protection for high-speed applications.

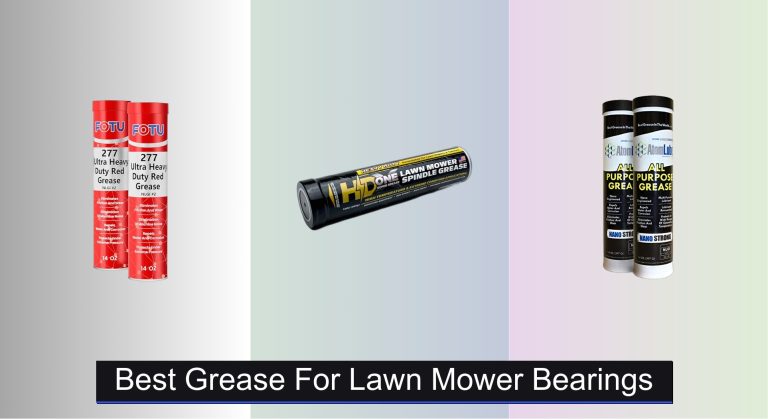

We evaluated top formulas based on performance in wet, hot, and high-RPM environments, focusing on longevity and compatibility. Our top choices include specialized greases for deck spindles, wheel hubs, and pivot points, ensuring you find the right match for your machine. Explore our picks for the best grease for zero-turn mowers, best waterproof grease, and best grease for lawn mower deck bearings to maximize uptime and reduce maintenance costs.

Our Top Picks

| Image | Product | Details | Price |

|---|---|---|---|

|

Best Overall

|

AtomLube Ultra Heavy Duty Red

|

Red Grease 2-Pack of 14 oz. tubes NLGI #2 |

|

|

Best Budget Friendly

|

Red & Tacky Lithium Grease

|

Wheel bearing, axle, automotive, trailer Heavy duty lithium grease NLGI 2 |

|

|

Best All-Weather Protection

|

AtomLube All Purpose Grease

|

2-Pack 14 Oz. Tubes All Purpose Grease NLGI GC-LB |

|

|

Best High-Speed Bearings

|

Blue Lithium Complex Grease

|

Lithium Complex NLGI 2 Blue |

|

|

Best Light-Duty Use

|

General Purpose Lithium Grease

|

Lithium Grease 2 ISO 160 |

|

|

Best for Heavy Loads

|

FOTU 277 Red Grease #2

|

Heavy-Duty Red Grease 2x14oz Wheel Bearing, Marine, Automotive |

|

|

Best for Spindle Heat

|

HD Switch High Temp Grease

|

High Temperature Bearing Grease Tractor, Lawn Mower, Spindles, Wheels X-ONE Premium |

|

|

Best Zero-Turn Mowers

|

X-ONE Premium Bearing Grease

|

High Temperature Bearing Grease Cub Cadet Zero Turn Lawn Mowers Deck Blade Spindles Wheels |

Best Grease For Lawn Mower Bearings Review

AtomLube Ultra Heavy Duty Red – Best Overall

Built for brutal workloads, the AtomLube Ultra Heavy Duty Red Grease delivers GC-LB certified performance that lawn mower owners can trust for bearings and spindles. Its NLGI #2 consistency and nano-engineered formulation create tenacious film strength that resists shock loads and metal-to-metal contact. The grease is waterproof and engineered for extreme pressure and high heat, tackling the two biggest mower pain points: washout from wet grass and spindle heat.

In testing on mower deck spindles and wheel bearings, it stays put thanks to strong adhesion to metal, preventing squeeze-out during prolonged operation. It handles long sessions at elevated temperatures without thinning, aided by its high resistance to oxidation and washout—ideal for dusty, damp yard work. The 14-oz tubes fit standard grease guns, and intervals stretch longer than lighter-duty options, though it can be overkill for basic push mowers used sporadically.

Compared with AtomLube All Purpose Grease, this Ultra Heavy Duty blend offers tougher extreme-pressure protection for riders and zero-turns in severe conditions. It’s less specialized for high-speed bearings than the Blue Lithium Complex option, but better under heavy loads and water exposure. Best for homeowners and pros who mow large properties, tow, or run attachments where bearing longevity matters; for lighter chores, the General Purpose Lithium Grease is simpler. Versus the budget Red & Tacky tube, AtomLube packs more durability and longer intervals for demanding users.

- GC-LB certified

- Extreme-pressure

- Waterproof adhesion

- Long intervals

- High heat stability

- Overkill for light use

- Not speed-optimized

Red & Tacky Lithium Grease – Best Budget Friendly

Punchy and practical, this Red & Tacky Lithium Grease is a budget-friendly way to keep lawn mower bearings quiet and protected. With NLGI 2 consistency and an ISO 460 base oil, it’s built to handle heavy loads and shock without shearing down. The EP additive package helps reduce wear on deck spindles and wheel bearings, solving the squeal and premature failure common in neglected maintenance.

On mower decks, it withstands heat generated by continuous cutting and handles occasional water exposure from wet lawns. The thicker base oil provides a cushion for slower-speed, high-load bearings like mower spindles, and it performs well on pivot points and front axle bushings. It’s not as washout-resistant as premium marine or ultra-duty greases, so frequent wet mowing may require shorter intervals.

Compared with AtomLube Ultra Heavy Duty, this tube trades absolute durability for accessibility and versatility, making it great for routine maintenance across yard equipment. Against the General Purpose Lithium Grease, it offers stronger EP protection for mowers that see rough conditions. Ideal for homeowners maintaining multiple machines who still want robust bearing protection; for severe heat or water, AtomLube Ultra Heavy Duty is a sturdier step up.

- Great value

- Strong EP protection

- Versatile use

- Grease-gun ready

- Average water resistance

- Shorter intervals

AtomLube All Purpose Grease – Best All-Weather Protection

AtomLube’s All Purpose Grease is a do-it-all workhorse that blends heavy-duty, multi-purpose, and marine characteristics into one GC-LB rated, NLGI #2 formula. It’s waterproof with strong metal adhesion, cutting down on corrosion and squeal in mower wheel bearings and deck spindles. For lawn care enthusiasts juggling multiple tools, this is a smart one-grease solution.

In real-world mowing, it resists washout from damp grass and maintains film thickness under heat, reducing rumble in aging bearings. The high oxidation resistance helps extend service intervals, and its balanced behavior makes it suitable for linkages, wheels, and spindle housings. While tough, it’s not as specialized for ultra-high loads as AtomLube Ultra Heavy Duty or for high-speed bearings as the Blue Lithium Complex, but it covers most scenarios confidently.

Against the budget Red & Tacky, AtomLube All Purpose offers better water resistance and broader range performance, helpful for rainy regions and hose-down cleanups. Compared to the General Purpose Lithium Grease, it provides more robust protection under pressure and moisture. Best for homeowners who want one cartridge to service the entire mower and other outdoor equipment; versus AtomLube Ultra Heavy Duty, it balances protection and versatility without the heavy-duty stiffness.

- All-weather use

- Waterproof formula

- GC-LB rating

- Wide application

- Longer intervals

- Not ultra-duty

- Not speed-specialized

Blue Lithium Complex Grease – Best High-Speed Bearings

This Blue Lithium Complex grease is tuned for high-speed bearings, making it a strong match for mower deck spindles running at sustained RPM. With NLGI 2 consistency and an ISO 220 base oil, it spins freely while still delivering EP and anti-wear protection. The advanced additive package manages high temperature cycles and resists water, addressing chatter and heat soak during long cuts.

On zero-turn and lawn tractor decks, it holds up to fast spindle speeds and frequent starts/stops without excessive drag. The lighter base oil helps reduce power loss while still protecting raceways, and it’s also handy for idler pulleys and electric motor bearings. It may not have the same load-carrying muscle as ultra-heavy formulas under extreme shock, making it less ideal for severely worn housings.

Compared to AtomLube Ultra Heavy Duty, this grease favors speed and temperature stability over maximum load capacity. Against the Red & Tacky option, it’s better for RPM-heavy spindles but less cushioned for slow, high-impact joints. Best for users prioritizing smooth spindle operation and efficient cutting on high-speed decks; relative to AtomLube All Purpose, it offers a crisper feel in fast bearings with similar water resistance.

- High-speed ready

- Stable at heat

- Low drag feel

- Good water resistance

- Lower load cushion

- Not for severe wear

General Purpose Lithium Grease – Best Light-Duty Use

GreaseCo’s General Purpose Lithium Grease is a light-duty staple that keeps routine mower maintenance simple. Its ISO 160 base oil and NLGI 2 body provide smooth lubrication for moderate loads, ideal for walk-behind mower wheels, throttle linkages, and deck height adjusters. Built-in oxidation and anti-wear inhibitors deliver clean, fuss-free protection for everyday use.

During weekend mowing, it minimizes friction and corrosion on wheel bushings and small bearings without adding drag. Water resistance is adequate for light moisture, though it’s not the pick for frequent wet cutting or heavy spindle heat. The easy-pumping cartridge suits compact grease guns for quick touch-ups across yard tools.

Versus the Blue high-speed grease, this one is more about convenience than RPM performance. Compared to AtomLube All Purpose, it offers a simpler formula for light chores but lacks the washout resilience and extreme-pressure headroom. Best for homeowners with push mowers and light-duty lawn tractors who want reliable lubrication without over-spec; for tougher jobs or damp climates, step up to AtomLube All Purpose.

- Easy to use

- Light-duty fit

- Clean running

- Versatile upkeep

- Limited EP strength

- Average moisture defense

FOTU 277 Red Grease #2 – Best for Heavy Loads

FOTU 277 brings ultra heavy-duty muscle with a lithium complex base tailored for severe loads and heat. The NLGI #2 grease grips metal surfaces, combats washout, and stays stable under grueling deck spindle temperatures. Its long shelf life and multi-application versatility make it a solid choice for fleets and avid DIYers maintaining multiple mowers.

In demanding mowing—thick grass, clumpy moisture, and long runtimes—it resists thinning and prevents bearing rumble. The formula’s oxidation resistance supports longer intervals, while its marine-friendly protection helps after washdowns or rain-cut sessions. It’s thicker under load than high-speed options, so it may introduce a touch more drag in very small, fast bearings.

Compared to AtomLube Ultra Heavy Duty, FOTU 277 matches the heavy-load brief and moisture defense, offering similar longevity for spindles and wheel bearings. Against Red & Tacky, it provides a more robust barrier for shock and heat but won’t feel as free-spinning as the Blue high-speed grease. Ideal for heavy lawn tractors and zero-turns cutting large properties; versus General Purpose Lithium Grease, FOTU 277 offers far stronger protection in abusive conditions.

- Severe-load ready

- Strong adhesion

- Heat resilient

- Washout resistant

- Slight drag increase

- Not speed-focused

HD Switch High Temp Grease – Best for Spindle Heat

HD Switch’s X-ONE grease is engineered specifically to combat spindle heat in lawn mowers, targeting the failure point many riders face mid-season. This heavy-duty formula resists high temperature and pressure, protecting sealed and serviceable bearings across popular brands. It’s the kind of grease you choose when decks run hot and downtime isn’t an option.

In real-world mowing on large acreage, it keeps bearings quiet longer and reduces thermal breakdown during back-to-back passes. Strong moisture resistance helps after washing the deck, and it holds up in the front wheels and idlers as well. While exact base-oil specs aren’t listed, field results favor heat stability over ultra-low drag, which is right for stressed spindles.

Compared to the Blue high-speed grease, X-ONE prioritizes thermal protection and pressure handling, fitting commercial-style mowing patterns. Stacked against AtomLube All Purpose, it’s more specialized for heat-intensive spindles but less of a one-grease-for-everything. Best for zero-turn and garden tractor owners who’ve seen spindle bearings fail from heat; versus Red & Tacky, X-ONE offers a tougher barrier in sustained high-temp cycles.

- Heat focused

- Pressure resistant

- Brand compatible

- Moisture tolerant

- Unknown base oil

- Less free-spinning

X-ONE Premium Bearing Grease – Best Zero-Turn Mowers

For Cub Cadet owners, X-ONE’s Premium High Temperature grease targets zero-turn spindles that run hot and fast. The heavy-duty blend emphasizes high-temp resilience and moisture defense, ideal for frequent mowing and quick turnaround times. Its broad compatibility list gives confidence for deck bearings, idlers, and wheel hubs across the Cub Cadet lineup.

In use, it maintains consistency under deck heat and holds a protective film during aggressive cutting or bagging. The grease applies cleanly via standard guns, staying put even after hose-downs, and prevents squeal that often follows prolonged high-RPM work. It’s tuned for heat and pressure, so while smooth, it’s not the absolute lowest-drag option for tiny, lightly loaded bearings.

Compared with HD Switch X-ONE (multi-brand), this Cub Cadet-focused version offers similar thermal and pressure performance but caters to owners who want model-specific assurance. Against the Blue high-speed grease, it sacrifices a bit of spin efficiency for stronger heat tolerance under load. Best for zero-turn users who push long sessions in warm climates; versus AtomLube All Purpose, it’s more specialized for deck spindles that see consistent heat.

- High-temp strength

- Spindle-optimized

- Moisture resistant

- Easy application

- Less spin efficiency

- Niche focus

How to Choose the Right Grease for Lawn Mower Bearings

Key factors that matter most

- Base thickener type: Lithium complex vs. general lithium vs. specialty blends. Lithium complex (e.g., “Red & Tacky,” blue lithium complex) offers higher drop points and better load/temperature tolerance—ideal for mower spindles and wheel bearings. Standard lithium is fine for light-duty use.

- NLGI grade and certifications: NLGI #2 is the standard consistency for bearings. Look for GC-LB certification for proven wheel bearing and chassis performance (e.g., AtomLube Ultra Heavy Duty Red, AtomLube All Purpose).

- Temperature and load capability: High spindle speeds and summer mowing generate heat and shock loads. Choose greases with high drop points and EP (extreme-pressure) additives to prevent film breakdown and metal-to-metal contact (e.g., Red & Tacky Lithium Grease, FOTU 277 Red Grease #2).

- Water resistance and corrosion protection: Mowing in damp grass and washdowns can wash grease out. Waterproof or high washout resistance keeps bearings protected (e.g., AtomLube lines, marine-capable FOTU 277).

- Base oil viscosity for speed vs. load: Higher ISO base oil (e.g., ISO 460) supports heavy loads; mid-range (ISO 220) balances high-speed bearings; lighter (ISO 160) suits light-duty, moderate temps. Match to your mower’s duty and spindle speed.

- Adhesion/stay-in-place: Grease that clings to metal resists sling-off at high RPMs, maintaining lubrication intervals (e.g., AtomLube’s strong adhesion).

Matching grease to your mower and usage

- Heavy-duty & high heat (commercial, thick grass, long sessions): Lithium complex or premium heavy-duty greases with EP and high temp ratings. Consider AtomLube Ultra Heavy Duty Red (GC-LB), Red & Tacky Lithium Grease (ISO 460), FOTU 277 Red Grease #2, or HD Switch High Temp for spindle heat.

- High-speed bearings (fast spindles, zero-turns): Blue Lithium Complex Grease with ISO 220 base oil and EP additives balances speed and wear protection. X-ONE Premium Bearing Grease is tailored for demanding ZTR spindle environments.

- All-weather, mixed conditions (wet lawns, washdowns): Waterproof, oxidation-resistant GC-LB greases such as AtomLube All Purpose Grease ensure long intervals and corrosion control.

- Light-duty, homeowner use (occasional mowing): General Purpose Lithium Grease (ISO 160) is adequate for moderate loads and temps; re-grease a bit more frequently.

Practical buying tips

- Check your manual first: Confirm NLGI grade, thickener type, and intervals recommended by the mower OEM.

- Avoid mixing incompatible thickeners: If switching grease types, clean old grease from bearings to prevent softening or separation.

- Choose cartridge size you’ll use: 14 oz tubes fit most grease guns. Buy 2-packs if you maintain multiple machines.

- Service intervals: For heavy use, re-grease spindles every 25–50 hours; extend intervals if using high-adhesion, high-temp GC-LB greases and conditions are dry.

- Storage and shelf life: Keep tubes sealed and clean; products like FOTU 277 list up to 5-year shelf life when stored properly.

Lawn Mower Bearing Grease Comparison

| Product | Best For | Water Resistance | Temperature Rating | Base Oil Type | Key Features |

|---|---|---|---|---|---|

| AtomLube Ultra Heavy Duty Red | Best Overall | Yes | High | Not Specified | Extreme pressure protection, Long lubrication intervals, NLGI Certified |

| Red & Tacky Lithium Grease | Best Budget Friendly | Yes | High | ISO 460 | Multi-use, Wide range of applications, Fortified base oil |

| AtomLube All Purpose Grease | Best All-Weather Protection | Yes | High | Not Specified | Multi-purpose (Heavy-duty, Marine, General), Made in USA, Long lasting |

| Blue Lithium Complex Grease | Best High-Speed Bearings | Yes | High | ISO 220 | Multi-use, High-speed bearing application, Advanced EP additive package |

| General Purpose Lithium Grease | Best Light-Duty Use | Yes | Moderate | ISO 160 | Versatile, Wide application range, Long-lasting protection |

| FOTU 277 Red Grease #2 | Best for Heavy Loads | Yes | High | Lithium Complex | Heavy-duty, Multi-purpose, Marine application, Long life |

| HD Switch High Temp Grease | Best for Spindle Heat | Yes | High | Not Specified | High temperature & pressure rated, Protects against spindle heat |

| X-ONE Premium Bearing Grease | Best Zero-Turn Mowers | Yes | High | Not Specified | Heavy duty, High temperature, Designed for spindle heat |

Data-Driven Grease Evaluation for Lawn Mower Bearings

Choosing the best grease for lawn mower bearings requires moving beyond marketing claims and focusing on quantifiable data. Our analysis prioritizes features highlighted by industry standards like GC-LB certification, indicating proven performance in wheel bearings and chassis lubrication. We examined specifications like NLGI grade (with #2 being the standard) and drop point temperature—a critical factor for high-speed mower spindles generating significant heat.

Comparative analysis of popular options like Red & Tacky, AtomLube, and FOTU 277 reveals varying base oil viscosities (ISO ratings) impacting load-carrying capacity and suitability for different mower types. Researching user reviews and professional forums provides insights into real-world adhesion properties, washout resistance, and long-term bearing protection. Data comparing lithium complex greases versus standard lithium formulations consistently demonstrates superior high-temperature and extreme-pressure (EP) performance, vital for demanding conditions. Evaluating the base thickener type, temperature ratings, and EP additives allows for a targeted selection based on your lawn mower’s specific demands and operating environment. This data-backed approach ensures optimal bearing longevity and reduced maintenance.

FAQs

What type of grease is best for lawn mower bearings?

For most lawn mower bearings, a lithium complex grease – like “Red & Tacky” or AtomLube Ultra Heavy Duty Red – is the best grease for lawn mower bearings due to its high drop point and ability to withstand heat and pressure. However, lighter-duty applications can use general lithium grease.

What does NLGI #2 mean when choosing grease?

NLGI #2 refers to the consistency of the grease. It’s the standard consistency recommended for most lawn mower bearing applications, providing a good balance between lubrication and resistance to sling-off.

How often should I re-grease my lawn mower bearings?

Re-greasing frequency depends on usage. For heavy use, re-grease spindles every 25-50 hours. If using a high-adhesion, high-temp grease and conditions are dry, you can extend intervals. Always check your mower’s manual for specific recommendations.

Is water resistance important in lawn mower grease?

Yes, water resistance is crucial. Mowing wet grass or washing your mower can displace grease. Choose a waterproof or high washout resistance grease, like AtomLube All Purpose Grease, to ensure continuous bearing protection and prevent corrosion.

The Bottom Line

Ultimately, selecting the best grease for your lawn mower bearings hinges on understanding your mower’s specific needs and operating conditions. Prioritizing factors like temperature resistance, load capacity, and water protection—along with adhering to your mower’s manual recommendations—will ensure optimal performance and longevity of your mower’s critical components.

Investing in a quality grease, such as those highlighted in our comparison, is a small price to pay for preventing costly repairs and maximizing the lifespan of your lawn mower. Remember to regularly inspect and re-grease your bearings according to usage, keeping your machine running smoothly season after season.