When your Craftsman riding lawn mower will not move, it’s beyond frustrating—especially if the engine runs fine but the mower just won’t go. The quickest fix most of the time? Check that the parking brake is fully disengaged, the transmission bypass (freewheel) lever is not in “push” mode, and your drive belt hasn’t slipped off. These simple checks solve a large percentage of movement issues in minutes.

In this comprehensive guide, you’ll learn every common cause of a Craftsman riding mower that won’t move (forward or reverse), and step-by-step solutions from easy adjustments to deeper mechanical fixes. By the end, you’ll know how to diagnose belt problems, transmission bypass issues, hydrostatic fluid concerns, brake linkage faults, and more—plus how to prevent it from happening again.

Common Causes of a Craftsman Riding Lawn Mower Not Moving

- Parking brake engaged or stuck

- Hydrostatic transmission freewheel/bypass lever engaged

- Worn, broken, or thrown drive (ground) belt

- Idler pulley spring or tensioner failure

- Debris binding pulleys or belt path

- Sheared key or stripped hub on drive pulley

- Axle keys missing or broken (wheels spin freely but mower doesn’t move)

- Brake linkage or brake arm stuck (rust, debris, bent parts)

- Hydrostatic transmission fluid low/overheated/contaminated or internal failure

- Manual (gear) transmission clutch cable out of adjustment

- Dead/binding transaxle due to overloading or long storage

- Differential issues (clicking, no drive under load)

- Safety interlock preventing drive (rare; more often prevents starting)

How to Fix a Craftsman Riding Lawn Mower That Won’t Move

Below are multiple solution methods, ordered from quickest checks to advanced repairs. Always refer to your owner’s manual for your specific model (e.g., T110, T140, T210, LT2000, YT3000). Many Craftsman riding mowers use hydrostatic transmissions (Tuff Torq, Hydro-Gear), while others use manual/shift-on-the-go transaxles.

Important: Safety first

– Turn the engine off and remove the key.

– Engage the parking brake.

– Disconnect the spark plug wire to prevent accidental starting.

– If lifting the mower, use jack stands on a flat surface.

Method 1: Quick External Checks (5–10 minutes)

Diagnosing the Issue

If the mower starts but won’t move, first rule out simple obstructions and settings. Many “no movement” issues are due to the freewheel lever or brake.

Fix Steps

1) Verify parking brake is released

– Sit on the seat, press the brake pedal, and release the parking brake. The brake lever may be sticky—manually return it to the run position.

– If the brake feels jammed, move it back and forth a few times.

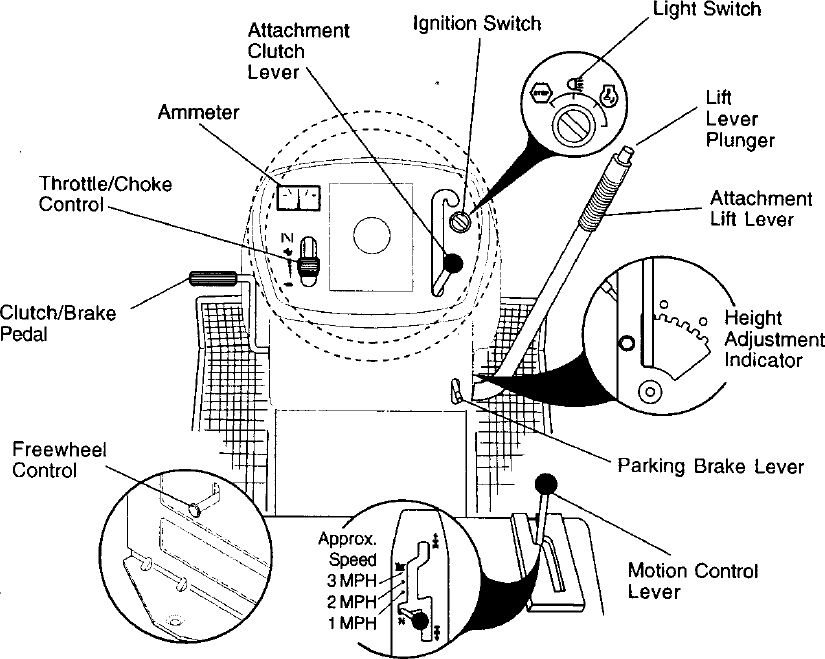

2) Check the freewheel/bypass lever

– At the rear of the mower/transaxle there’s a lever or pull pin used for pushing the mower without the engine running. If it’s engaged, the mower will not drive.

– Ensure it is in “Drive/Engaged” (consult the decal near the rear hitch or your manual). On many Craftsman models, push the rod back in or flip the lever downward.

3) Inspect for debris and belt derailment

– Look under the mower near the rear transaxle for sticks, vines, or mud caked around the belt and pulleys.

– Confirm the drive belt is on the engine pulley (above the deck area), idler pulleys, and transaxle pulley at the rear.

4) Check tire pressure and wheel pins

– Extremely low tire pressure can prevent movement under load. Inflate to the spec on the tire sidewall (commonly 10–14 PSI front, 10–12 PSI rear).

– Ensure rear wheels are fully seated and secured; missing keys in the rear axle hubs can cause spinning without drive.

Testing

- Reconnect spark plug, start the mower, and carefully test forward and reverse on flat ground.

Method 2: Drive Belt and Tensioner Repair (20–45 minutes)

If the belt is worn, glazed, stretched, broken, or has popped off, the mower won’t move. This is one of the most common causes.

Diagnosing the Issue

- Symptoms: Engine revs normally, no grinding sounds, mower won’t move or moves only on flat ground, belt looks loose or off-track.

- With the engine off, push on the drive belt midway between pulleys. Excessive slack or cracks indicate replacement.

Fix Steps

1) Identify the correct belt

– Look up your model number (sticker under the seat or on the frame) and order the OEM drive belt. Craftsman part numbers vary; resist using undersized/unlabeled belts—length and profile matter.

2) Remove deck (if required)

– Many Craftsman models require dropping the mower deck to access the ground drive belt.

– Pull the deck engagement cable off, remove retaining pins and links, slide deck out.

3) Release tension

– Use a wrench to relieve tension at the idler arm spring and slip off the belt (note routing). Take photos for reference.

4) Inspect pulleys and idler arm

– Spin pulleys by hand; they should spin freely without wobble or grinding. Check for bent idler arm, weak/broken tension spring, and rough bearings.

– Replace worn pulleys and the tension spring if stretched or rusty. A weak spring can cause slipping under load.

5) Install new belt

– Route the new belt according to the diagram under the footrest or manual. Ensure it sits in the pulley grooves correctly.

– Reapply tension and verify alignment. Reinstall deck if removed.

Testing

- Start the mower, slowly engage drive. Test on a slight incline. If it slips or squeals, recheck routing and tension.

Method 3: Brake Linkage and Stuck Brake Arm (15–30 minutes)

A seized brake mechanism on the transaxle can hold the mower in place even with the pedal up.

Diagnosing the Issue

- Symptom: Mower barely creeps, smells hot, or stalls when trying to move. Brake pedal feels stiff or doesn’t return smoothly.

- Observe the brake arm on the transaxle (small lever on the side with a return spring). With the pedal released, the arm should move freely.

Fix Steps

1) Lubricate and free the brake arm

– Spray penetrating oil at the brake arm pivot and the linkage joints. Work the arm by hand to free movement.

– Check the return spring is intact and has good tension.

2) Adjust brake linkage

– Some models have an adjustment nut on the brake linkage or cable. Loosen slightly to ensure the brake isn’t dragging when the pedal is released.

3) Inspect brake disc/pad

– If the brake disc is rusty or the caliper is stuck, disassemble carefully, clean surfaces with emery cloth, and reassemble. Replace worn pads.

Testing

- With wheels off the ground, spin them by hand with brake released—they should spin freely. Then test drive.

Method 4: Hydrostatic Transmission Issues (30–60 minutes)

Most newer Craftsman riders use hydrostatic drives. Incorrect freewheel position, air in the system, or low/old oil can cause no movement or weak drive.

Important: Many hydrostatic transaxles are sealed and not user-serviceable for oil changes. Check your manual. Overfilling or using the wrong fluid can cause damage.

Diagnosing the Issue

- Symptoms: Slow/no movement, only moves when cold then loses drive when hot, whine from transaxle, or sudden loss of drive after towing.

- Confirm freewheel lever is in the engaged position.

Fix Steps

1) Purge air from the hydrostatic system

– Put the mower on flat ground, disengage the deck, set to neutral.

– Start engine at low throttle, release brake.

– With freewheel lever in “Drive,” slowly move the forward lever/pedal to full forward and hold 5 seconds, then full reverse 5 seconds. Repeat 5–6 times.

– Shut off, then restart and test. This purges air after belt or transaxle service.

2) Inspect input pulley and fan

– With engine off, check the transaxle input pulley and plastic cooling fan above it. Broken fan blades or a loose pulley can cause overheating and poor drive. Replace if damaged.

3) Check for serviceable fluid

– If your transaxle has a service port or reservoir (some Tuff Torq models), check fluid level and condition. Dark/burnt fluid indicates overheating.

– Use manufacturer-specified oil (many use 20W-50 motor oil; some require specific hydro oil—verify by model).

– If fluid can be changed, perform a drain/refill and purge per the transaxle manufacturer’s procedure (see Tuff Torq or Hydro-Gear service manuals).

4) Address overheating

– Clean grass/debris from around the transaxle case and fan shroud. Heat kills hydro performance.

If there is still no movement after purge and belt/pulley checks, the hydrostatic unit may have internal failure (pump/motor wear).

Testing

- After purging and cleaning, test for strong forward and reverse on a slight hill. If drive fades as it warms, the hydro may be worn.

Method 5: Axle Keys, Wheel Hub, and Differential (15–45 minutes)

If the engine and pulleys spin but the mower won’t move under load, the axle-to-wheel connection might be slipping.

Diagnosing the Issue

- Symptom: One wheel spins freely by hand or both spin without moving the mower under load, sometimes with clicking sounds.

- Pull the rear wheel caps and check for missing/damaged keys or stripped hubs.

Fix Steps

1) Inspect wheel hubs and keys

– Remove the wheel retaining clip and washer. Slide off the wheel.

– Look for the square key in the axle keyway. Replace missing or sheared keys. Clean rust and apply anti-seize lightly.

2) Inspect differential input and axles

– Check for excessive play, broken snap rings, or oil leakage at axle seals (on serviceable units). If internal differential is damaged, replacement of the transaxle is often more economical.

Testing

- Reinstall wheels and test under load.

Method 6: Manual Transmission/Clutch Cable Adjustment (for non-hydro models) (20–30 minutes)

On gear-drive Craftsman riders, a stretched clutch/drive cable or worn belt will prevent engagement.

Diagnosing the Issue

- Symptom: Shifts into gear but no movement; moves only at high throttle; smell of belt burning.

- Observe the clutch idler arm when pressing the pedal—does it fully tension the belt?

Fix Steps

1) Adjust clutch cable

– Locate the adjustable ferrule on the clutch cable. Tighten to increase belt tension when the pedal is released.

– Check the idler spring and replace if stretched.

2) Replace worn drive belt

– Follow the belt replacement steps in Method 2.

Testing

- With engine running and brake released, ease the pedal out and verify strong engagement.

How to Prevent Future Drive Problems

- Clean undercarriage regularly: Grass buildup throws belts and overheats hydros.

- Inspect the drive belt each season; replace at the first signs of glazing, cracking, or stretching.

- Keep the transaxle cooling fan and fins clear of debris.

- Verify tire pressures monthly.

- Don’t tow heavy loads or push the mower downhill in freewheel for long distances—hydros can be damaged.

- Store on level ground; avoid parking with wet grass caked around pulleys.

- Use OEM belts and springs; off-spec parts cause chronic slipping.

Pro Tips

- Photograph belt routing before removal; Craftsman often has both deck and drive belts—don’t mix them up.

- Replace idler pulleys and the tension spring when you replace a severely worn belt; this prevents revisiting the same problem.

- If the mower only moves when cold and fails when hot, suspect hydrostatic wear or low fluid; cleaning and purging may help short-term, but plan for service.

- A chirping or squealing sound under the seat area under load usually means belt slip—inspect tensioner and spring.

- Use anti-seize on rear axle shafts to make future wheel removal easier; rusted wheels can seize to the axle.

- Check the freewheel lever after transporting the mower—delivery or moving can bump it into bypass.

- Keep a parts list handy: drive belt PN, idler spring PN, and your transaxle model (sticker on the case) to speed up future repairs.

When to Call a Professional

- Persistent no-drive after belt replacement, tensioner inspection, purge, and brake checks.

- Hydrostatic transaxle losing drive when warm or making loud whining/grinding.

- Oil leaks from the transaxle or visible cracks in the case.

- Differential or axle damage (broken gears, excessive play).

- You lack tools to safely lift/support the mower for undercarriage work.

What to look for in a service provider

– Experience with Craftsman/Troy-Bilt/Husqvarna riding mowers (similar platforms).

– Ability to source OEM parts and provide a written estimate.

– Diagnostic fee credit if you proceed with the repair.

Typical costs (estimates; vary by region)

– Drive belt and idler service: $120–$250 parts/labor.

– Brake service/adjustment: $80–$180.

– Hydrostatic transaxle replacement: $450–$900+ parts/labor (often more economical to replace mower on older units).

Warranty considerations

– If your mower is under warranty, do not open a sealed transaxle. Use authorized service and OEM parts to avoid voiding coverage.

FAQ

Q: My Craftsman mower runs, blades engage, but it won’t move. What should I check first?

A: Verify the parking brake is released, the freewheel/bypass lever is in “Drive,” and inspect the drive belt for derailment or damage. These are the fastest fixes and most common causes.

Q: How do I find the freewheel/bypass lever?

A: Look at the rear of the mower near the hitch plate or transaxle. It’s usually a pull-out rod or small lever. A decal often labels it “Freewheel” or “Bypass.” Push it in or set it to the “Drive” position per your manual.

Q: Can a bad battery cause the mower not to move?

A: A weak battery can affect electric PTOs and safety switches, but if the engine runs, lack of movement is typically mechanical (belt, brake, transaxle) rather than electrical. However, on some models with electronic controls, extremely low voltage can reduce hydro solenoid function—rare on Craftsman riders.

Q: How often should I replace the drive belt?

A: Inspect each season and replace every 2–4 years depending on use. Heavy mowing, heat, and debris can shorten belt life. If you see glazing, cracks, or the belt rides low in pulleys, replace it.

Q: Why does my mower move when cold but stop when it warms up?

A: This often indicates a hydrostatic transaxle losing efficiency when hot due to worn internal components or low/aged fluid. Clean the cooling fan and purge the system; if symptoms persist, professional service or replacement may be needed.

Q: My wheels spin but the mower doesn’t move under load. What’s wrong?

A: Check for missing/sheared axle keys in the rear wheel hubs and verify the hub splines aren’t stripped. Also inspect the drive belt tension and idler spring.

Q: Is it okay to tow my riding mower?

A: Only short distances and only with the freewheel/bypass engaged, at walking speed. Towing long distances or fast can damage the hydrostatic transmission.

Q: How do I know if my transaxle is sealed or serviceable?

A: Check your owner’s manual and the transaxle model tag (Tuff Torq K46, Hydro-Gear, etc.). Sealed units lack a fill port; serviceable units have a reservoir or fill plug with specified oil.

Alternative Solutions

If major hydrostatic failure is diagnosed, you have options beyond full replacement:

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace with new OEM transaxle | Restores like-new performance, reliable | Highest cost | Newer mowers worth investing in |

| Rebuild transaxle (seal kit, fluid, parts) | Lower cost than new, educational | Requires tools, time; not always possible on sealed units | Skilled DIYers with rebuildable models |

| Upgrade to heavier-duty transaxle (if compatible) | Improved durability | Compatibility and fabrication challenges | Enthusiasts upgrading older frames |

| Replace mower | New warranty, updated features | Highest overall cost | Older units with multiple failures |

Get Your Craftsman Mower Moving Again

By following this guide, you now have multiple proven solutions to fix a Craftsman riding lawn mower that will not move:

– Quick checks: parking brake, freewheel/bypass lever, tire pressure

– Drive system repairs: belt routing/replacement, idler pulleys, tension spring

– Brake linkage cleaning and adjustment

– Hydrostatic maintenance: purge air, clean cooling fan, check fluid (if serviceable)

– Axle keys and hub inspections for slipping under load

– Manual transmission clutch and cable adjustments

Start with the simple checks—they solve most cases in minutes. With a fresh belt, proper tension, and a clean, cool-running transaxle, your Craftsman will deliver solid drive again.

Have you fixed your Craftsman mower not moving? Share what worked in the comments to help fellow owners. Found this helpful? Bookmark it for your next tune-up. If you’re still stuck, describe your model number and symptoms for personalized advice.