Nothing slows down mowing day like a Toro lawn mower self propel not working when you need it most. The quick fix in many cases is to tighten or adjust the drive cable at the handle—loose cable tension is a common cause. If that doesn’t solve it, checking the drive belt for wear or the wheels for stripped gears can restore your self-propel function fast.

In this comprehensive guide, you’ll learn every common reason Toro self-propel stops working and exactly how to fix it—step by step. We’ll cover cable adjustment, belt replacement, wheel gear inspection, transmission checks, and simple maintenance to keep your mower pulling strong. By the end, you’ll have multiple solutions from simple to advanced and know when it’s time to call a pro.

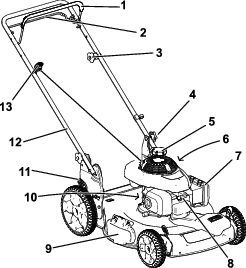

Common Causes of Toro Self-Propel Not Working

- Loose or stretched drive cable: The lever pulls but doesn’t engage the transmission enough.

- Worn or broken drive belt: The engine spins, but power doesn’t reach the wheels.

- Stripped wheel gears (pinion/ratchets): The wheels freewheel forward; gears inside the wheels are worn.

- Dirty or seized drive components: Grass packed around the drive wheels, axle, or belt cover.

- Faulty transmission/gearbox: Internal gears worn (common on high-hour units).

- Misadjusted drive engagement: Cable housing not seated properly at the handle or transmission bracket.

- Wrong wheel direction (ratchet one-way bearings): Wheels installed on the wrong side or bearings seized.

- Drive pulley slippage: Oil or debris on the engine or transmission pulleys.

- Bent idler/tensioner arm or weak spring (belt not tensioned): Belt won’t grip under load.

How to Fix Toro Self-Propel Not Working

Before you start: Disconnect the spark plug boot to prevent accidental starts. Turn the fuel valve off if equipped, and drain the fuel if tipping the mower is required. Always tip the mower with the carburetor/air filter side up to avoid flooding.

Method 1: Adjust or Replace the Drive Cable (Fastest Fix)

Many Toro Recycler, Personal Pace, and SmartStow models use a drive cable from the handle to the transmission. Over time, cables stretch and reduce engagement.

Diagnosing the Issue

- Squeeze the self-propel lever or push handle (Personal Pace). If there’s slack, or the mower doesn’t try to move, the cable may be loose.

- Watch the transmission lever at the front/rear (depending on model) as you engage the handle. If it barely moves, adjust cable tension.

Fix Steps

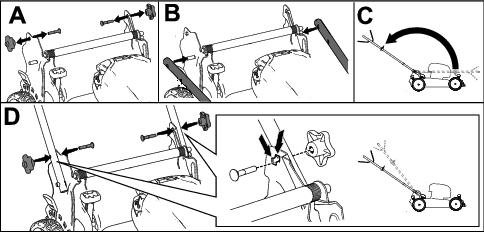

1) Locate the drive cable adjuster:

– Standard lever style: Inline barrel adjuster near handle or at cable mount bracket.

– Personal Pace: Cable attaches to the control bail/push handle and a spring at the transmission.

2) Adjust tension:

– Turn the adjuster nut or barrel to shorten the cable housing (clockwise typically increases tension).

– Aim for slight free play at the lever (about 1/8–1/4 inch) but full engagement when squeezed.

3) Verify the cable housing seats fully in the bracket at the handle and transmission. Reseat if popped out.

4) If the cable is frayed, seized, or adjustment runs out, replace it:

– Note the model and serial number (on deck sticker) to order the correct Toro drive cable.

– Unhook at handle and transmission, route the new cable the same way, and adjust.

Testing

- Reconnect the spark plug, start the mower, and engage the drive on flat ground.

- If the wheels engage quickly and pull under moderate resistance, the cable fix worked.

Time: 10–20 minutes for adjustment; 20–40 minutes for replacement.

Method 2: Inspect and Replace the Drive Belt

A loose, worn, or broken belt is a top reason the self-propel quits. Belts stretch and glaze over time, especially with heavy grass or debris.

Diagnosing the Issue

- When you engage self-propel, you feel the lever tightening but the mower doesn’t move.

- With the mower off and plug wire removed, tilt it safely and remove the belt cover. If the belt is cracked, thin, or shiny, replace it.

Fix Steps

1) Access the belt:

– Remove the blade control bail tie-down (if any), then tilt mower with air filter up.

– Remove the plastic belt cover/guard (usually Torx or hex screws).

– Inspect belt routing around the engine pulley, idler/tensioner, and transmission pulley.

2) Remove the belt:

– Slip belt off the engine pulley carefully (use gloves).

– Release belt from idler and transmission pulley.

– Inspect pulleys and idler arm; remove packed grass and mud.

3) Install a new Toro OEM belt:

– Route exactly as the diagram under the cover or from the manual.

– Ensure belt sits fully in pulley grooves and around the idler/tensioner.

4) Check tensioner spring and idler wheel:

– The idler should pivot freely and the spring should provide firm tension.

– Replace a weak spring or seized idler to prevent immediate re-failure.

5) Reinstall cover and lower mower.

Testing

- Start the mower, engage the drive, and walk forward. If it moves smoothly and consistently, the belt fix is complete.

Time: 30–60 minutes. Replace belts every 2–3 seasons depending on use.

Method 3: Check Wheels, Pinion Gears, and One-Way Bearings

Toro front- or rear-wheel drive mowers often rely on a small gear on the axle/pinion that meshes with gears inside the wheels, or one-way (ratchet) bearings built into the wheel hub.

Diagnosing the Issue

- The mower rolls freely forward but locks backward normally, yet doesn’t self-propel under load—often stripped wheel gear.

- You hear grinding or clicking when engaging self-propel.

- One wheel drives but the other doesn’t.

Fix Steps

1) Remove the wheel(s):

– With spark plug off, use a socket to remove the wheel nut/bolt.

– Note any washers, spacers, and the order of parts.

2) Inspect components:

– Look for worn or rounded teeth on the wheel gear or pinion gear.

– Check for dirt/grass packed inside the wheel hub.

– On one-way bearing wheels, spin the inner race: it should spin freely one direction and lock the other. If it slips both ways or is seized, replace the wheel.

3) Clean and lubricate correctly:

– Remove debris; wipe parts clean.

– Use a dry PTFE spray or light silicone on metal gear faces sparingly. Avoid grease on ratchet bearings unless Toro specifies; grease can attract dirt and cause slip.

4) Replace worn parts:

– Install new wheel(s), pinion gear, or key/clip as needed.

– Ensure left/right wheels are on the correct sides if they’re directional.

Testing

- Reinstall and test on pavement or short grass. If the wheels now “bite” and pull, the issue was gear-related.

Time: 20–45 minutes. Wheels and pinions are inexpensive and commonly replaced.

Method 4: Service the Transmission and Pulleys

If the cable and belt are good and wheel gears are fine, the transmission may be worn or the pulleys contaminated.

Diagnosing the Issue

- Engagement feels normal, belt spins, but wheels don’t move or move weakly.

- Oil/grease contamination on pulleys causing belt slip.

- Excess play on the transmission input shaft.

Fix Steps

1) Clean pulleys:

– Remove the belt and wipe engine and transmission pulleys with isopropyl alcohol or brake cleaner. Dry thoroughly.

– Remove any rust lip with fine emery cloth.

2) Check the transmission lever and linkage:

– Ensure the actuation lever at the transmission moves through full range when the handle is engaged.

– Lubricate pivot points with light machine oil.

3) Inspect transmission:

– Spin the output gear/axle by hand. If it’s gritty or binds, overhaul or replace the transmission.

– Check the axle keys and E-clips; replace missing or damaged retainers.

4) Replace the transmission (if needed):

– Order the correct Toro transmission by model/serial.

– Remove wheels, belt, and mounting bolts. Swap the unit and reassemble in reverse order.

Testing

- After reassembly, test on a small incline to verify consistent pull without belt squeal.

Time: Cleaning 20–30 minutes; transmission replacement 60–120 minutes.

Prevention Tips and Maintenance Advice

- Keep the belt area clean: After mowing, tip the mower safely and remove packed grass from the belt cover and pulleys.

- Adjust cable yearly: Minor tweaks prevent slip and premature belt wear.

- Replace belts proactively: Every 2–3 seasons for average lawns, sooner in heavy use.

- Clean wheel hubs: Dirt buildup accelerates gear and bearing wear.

- Use the correct replacement parts: Toro OEM belts and cables maintain proper length and grip.

- Store dry: Moisture promotes rust on pulleys and gears, leading to slip.

- Avoid riding the self-propel on tall grass: Let the blade cut the top layer first to reduce drive strain.

Step-by-Step Troubleshooting Flow

1) Safety first: Disconnect spark plug; tip mower with air filter up.

2) Visual check: Remove belt cover; clear debris.

3) Cable check: Adjust tension; replace if frayed or slack persists.

4) Belt inspection: Replace if worn, glazed, or loose.

5) Wheel/gear check: Inspect wheel hubs, pinion gears, and bearings; replace as needed.

6) Pulley/transmission check: Clean pulleys; verify tensioner spring; evaluate transmission.

7) Test after each step to isolate the fix.

Pro Tips

- Important: Always support the mower securely when tipped; never rely on a loose handle to hold it.

- Mark parts orientation: Take photos before disassembly so washers and spacers go back in the correct order.

- Torque matters: When removing the blade to access some belt routes, torque the blade bolt to manufacturer spec (often around 60 ft-lb; check your manual).

- Don’t over-tighten the cable: Excess tension can cause constant belt slip or premature transmission wear.

- Replace in pairs: If one wheel gear is stripped, the other is often close behind; swap both to restore balance.

- Belt squeal = slip: If you hear squealing under load, the belt is loose, glazed, oily, or the tensioner spring is weak.

- Keep a spare belt and cable on hand: Minimizes downtime mid-season.

Professional Help

- Signs you need a pro:

- Transmission grinds, binds, or leaks grease.

- Axle is bent or uneven wheel height after impacts.

- You’ve replaced cable and belt but drive still fails under load.

- Choosing a service provider:

- Authorized Toro service center with access to OEM parts and service bulletins.

- Clear labor rates and warranty on repairs.

- Typical costs:

- Cable: $20–$40 parts; $60–$120 installed.

- Belt: $15–$35 parts; $60–$120 installed.

- Wheels/gears: $15–$40 per wheel; $50–$100 labor.

- Transmission: $90–$180 parts; $120–$250 labor.

- Warranty considerations:

- Check your model’s warranty period (often 2–3 years residential). Drive system issues may be covered if not due to wear/abuse.

- Keep receipts and follow maintenance recommendations to avoid claim denial.

FAQ

Q: Why does my Toro self-propel only work sometimes?

A: Intermittent engagement usually points to a stretched cable or slipping belt. Heat can increase belt slip. Adjust the cable first, then inspect/replace the belt and clean the pulleys.

Q: My mower pulls weakly uphill. What should I check?

A: Verify belt tension and condition, ensure the idler spring is strong, and check wheel hubs for stripped gears. Also clean debris around the transmission and wheels; packed grass causes drag.

Q: Can I use a non-OEM belt on my Toro?

A: It’s not recommended. Toro belts are sized for specific pulley diameters and tensioners. Universal belts can be slightly off in length/width, causing chronic slip or premature wear.

Q: How do I know if the transmission is bad?

A: If the belt and cable are good and the transmission input spins but the outputs don’t turn or grind, internal gears are likely worn. Excessive play or noise under load is a strong indicator.

Q: Do I need to remove the blade to replace the belt?

A: On some Toro models, yes; on others, the belt can be snaked around the blade adapter. Check your specific model’s manual for routing and access. If removing, secure the blade and torque correctly on reinstallation.

Q: The wheels lock when pushing backward. Is that normal?

A: Many self-propel mowers use one-way clutches that allow free forward rolling and limit backward rolling. If the wheels fully lock or grind backward, inspect and clean the ratchet mechanism or replace the wheel.

Q: What regular maintenance keeps self-propel working?

A: Seasonal cable adjustment, belt inspection/replacement, cleaning under the belt cover, and periodic wheel hub cleaning. Store the mower in a dry area and avoid washing directly into bearings.

Alternative Solutions

If repeated drive failures occur or repair costs approach the mower’s value, consider alternatives.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace transmission assembly | Restores like-new drive; reliable | Higher parts/labor cost | Mowers in good overall condition |

| Upgrade to newer Toro Personal Pace model | Improved ergonomics and drive | Highest cost; new purchase | Heavy users, large lawns |

| Switch to maintenance-free electric self-propel | Low maintenance; instant torque | Battery cycle limits; higher upfront | Small–medium lawns, quiet operation |

| Manual push conversion (disconnect drive) | No repair costs | Harder to mow; slower | Small flat lawns, budget stopgap |

Keep Your Toro Running Smoothly

Following this guide, you now have multiple ways to fix a Toro lawn mower self propel not working:

– Quick cable adjustment or replacement

– Drive belt inspection and replacement

– Wheel gear and one-way bearing checks

– Pulley cleaning and transmission service or replacement

Tackle the steps in order—from simplest to more advanced—and you’ll usually restore full pulling power in under an hour. Keep the belt area clean, adjust the cable each season, and use OEM parts to maintain reliable self-propel.

Have you fixed your Toro’s self-propel issue? Share what worked in the comments to help other readers. Found this helpful? Bookmark it for your next tune-up. With these steps, your Toro self-propel will be back to making mowing fast and effortless.